Hi there!

I am currently trying to finalise my design for the system that will power our small house. We are fully off grid.

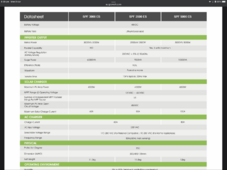

The system will be quite simple - compared to what some blokes here are running here and there - with initially 20 panels at 415w, 2 hybrid inverters from Growatt, and 10kw battery bank also from Growatt. ( final plan intends 30 panels. With 3 inverters and 15Kw battery total )

Now I have done a lot of reading through this forum and the beginners section and yet I can’t get to a conclusive solid answer for those 3 things:

My first query is regarding the connections of the panels. Being an AiO type inverter, I will run 1 string of 10 panels per inverter. Now the question remains Series or parallels-series? From what I can understand the Growatt inverter couldn’t support 10 panels in parallel, because the total A of each string panel would be above 120A so I figure series is the way to go, but maybe I am missing something or I could benefit from having a Para-series? At this point I am set for series, I am wondering if the length of the end cables have to be identical before they reach the inverter?

If that helps to answer the questions, the panels are all oriented and laying next to each other and of the same brand / type/ size on one big array.

My second question is regarding the gauge wire of the cable that will go from the inverters to the AC power board of the house.

The inverters and battery are located about 25 meters away from the house in they own little shed. I will have a breaker located next to the inverters, and then a long cable will run underground in a conduit to reach the house. I cannot be sure about what gauge would be safe to run here. From what I have read it seems that 16mm2 should do the trick but I was reading about the surge power on the inverter being 10kva so I wondered if my cable was too thin to handle that much or is it just the inverters capability…. Confused

My last question is regarding earthing - or grounding - has I have read a lot about the topic but still can’t make solid answers with it.

The earthing of the house I understand. A big long copper rod in the ground and a cable clamped or welded to it. But again what gauge?

Also nobody mentions anywhere if the DC circuit and AC circuit can share the same earth?

Do I need a separate earthing for the batteries/inverters/panels or do they have to link with the house’s earth?

Panel earthing is also never mentioned. Does the frame attached to the rails connected to a roof is enough to ground those or to they need to be also running an earth wire and if so does it follow the same rules - as in no loop - and therefore should meet with the earthing of the batteries and inverters?

I could run a long earth cable in the same duct as the AC load wire and have it run back to the shed to connect a common earth with the DC circuit if needed. But agin that seems odd.

Ideally I’d like to run my earthing directly out from the breaker that is located after the inverter and keep the earthing rod next to the solar shed. In that case is it ok to assume that the Ac load cable that runs underground is safe to carry the earth back with him?

Sorry of it is a bunch of silly question but I am getting mixed answers and since I am carrying out all the work my self I need to be certain.

Thanks for your help. I have tried to go though as much threads and beginners guide as possible but it seems that some things just get brushed off completely.

Hopefully I can get some definitive answers here, thanks

I am currently trying to finalise my design for the system that will power our small house. We are fully off grid.

The system will be quite simple - compared to what some blokes here are running here and there - with initially 20 panels at 415w, 2 hybrid inverters from Growatt, and 10kw battery bank also from Growatt. ( final plan intends 30 panels. With 3 inverters and 15Kw battery total )

Now I have done a lot of reading through this forum and the beginners section and yet I can’t get to a conclusive solid answer for those 3 things:

My first query is regarding the connections of the panels. Being an AiO type inverter, I will run 1 string of 10 panels per inverter. Now the question remains Series or parallels-series? From what I can understand the Growatt inverter couldn’t support 10 panels in parallel, because the total A of each string panel would be above 120A so I figure series is the way to go, but maybe I am missing something or I could benefit from having a Para-series? At this point I am set for series, I am wondering if the length of the end cables have to be identical before they reach the inverter?

If that helps to answer the questions, the panels are all oriented and laying next to each other and of the same brand / type/ size on one big array.

My second question is regarding the gauge wire of the cable that will go from the inverters to the AC power board of the house.

The inverters and battery are located about 25 meters away from the house in they own little shed. I will have a breaker located next to the inverters, and then a long cable will run underground in a conduit to reach the house. I cannot be sure about what gauge would be safe to run here. From what I have read it seems that 16mm2 should do the trick but I was reading about the surge power on the inverter being 10kva so I wondered if my cable was too thin to handle that much or is it just the inverters capability…. Confused

My last question is regarding earthing - or grounding - has I have read a lot about the topic but still can’t make solid answers with it.

The earthing of the house I understand. A big long copper rod in the ground and a cable clamped or welded to it. But again what gauge?

Also nobody mentions anywhere if the DC circuit and AC circuit can share the same earth?

Do I need a separate earthing for the batteries/inverters/panels or do they have to link with the house’s earth?

Panel earthing is also never mentioned. Does the frame attached to the rails connected to a roof is enough to ground those or to they need to be also running an earth wire and if so does it follow the same rules - as in no loop - and therefore should meet with the earthing of the batteries and inverters?

I could run a long earth cable in the same duct as the AC load wire and have it run back to the shed to connect a common earth with the DC circuit if needed. But agin that seems odd.

Ideally I’d like to run my earthing directly out from the breaker that is located after the inverter and keep the earthing rod next to the solar shed. In that case is it ok to assume that the Ac load cable that runs underground is safe to carry the earth back with him?

Sorry of it is a bunch of silly question but I am getting mixed answers and since I am carrying out all the work my self I need to be certain.

Thanks for your help. I have tried to go though as much threads and beginners guide as possible but it seems that some things just get brushed off completely.

Hopefully I can get some definitive answers here, thanks