liberumyu

New Member

- Joined

- Jul 2, 2022

- Messages

- 68

Hi all.

I have decided to migrate my system from EASUN to DEYE and from attic to garage.

Drivers for this change are hot conditions in attic during summer requiring AC to run most of the day and EASUN inverters switching to bypass when any of phases get overloaded which happens every time AC starts (irony ).

).

System will consist of:

- 2x DEYE SUN-12K-SG04LP3-EU as master and slave

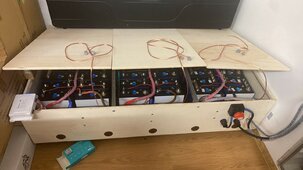

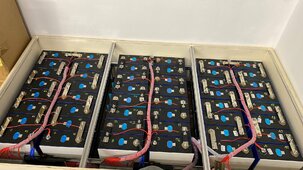

- 3x EVE LiFePo4 280ah battery banks 16s with JK BMS (already running for 2 years)

- 1x EVE LiFePo4 320ah battery bank 16s with JK BMS (in balancing as we speak)

- 1x 18s 415W array (already running for 2 years)

- 1x 12s 460W array to be installed

So now I’ve got my equipment and works are on. Photos will follow.

I’m not the guy throwing manuals to the bin and scraping data from forums but I got some good advice from @houseofancients @silverstone @uksa007 for which I’m thankful very much.

See you with comments and criticisms below, all is welcome to make this project better solution than initial one.

I have decided to migrate my system from EASUN to DEYE and from attic to garage.

Drivers for this change are hot conditions in attic during summer requiring AC to run most of the day and EASUN inverters switching to bypass when any of phases get overloaded which happens every time AC starts (irony

System will consist of:

- 2x DEYE SUN-12K-SG04LP3-EU as master and slave

- 3x EVE LiFePo4 280ah battery banks 16s with JK BMS (already running for 2 years)

- 1x EVE LiFePo4 320ah battery bank 16s with JK BMS (in balancing as we speak)

- 1x 18s 415W array (already running for 2 years)

- 1x 12s 460W array to be installed

So now I’ve got my equipment and works are on. Photos will follow.

I’m not the guy throwing manuals to the bin and scraping data from forums but I got some good advice from @houseofancients @silverstone @uksa007 for which I’m thankful very much.

See you with comments and criticisms below, all is welcome to make this project better solution than initial one.