ArthurEld

Solar Wizard

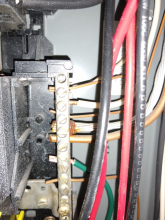

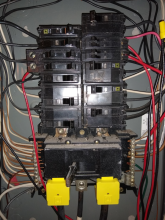

Guys, my main electrical panel wiring is a scary tangled up mess.

Since I am adding a Reliance transfer switch I will be adding a lot more wires and wire nuts.

It doesn't help that I have minimal electrical experience.

But, I am going to clean up the mess and I am going to add my new wires neatly.

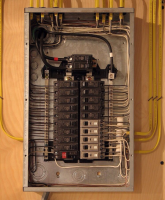

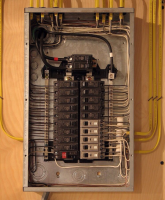

Here is one of the better examples I have found and there are many good examples.

I picked this one because it shows extra wire neatly coiled up and tucked away. I am hesitant to cut all of my transfer switch wires off but I probably just need to get over that and cut the wires.

My neutrals and grounds go to both sides. I guess it doesn't matter but it looks like crap.

Another thing that concerns me is that my main breaker is at the bottom. The wires for everything I want to do typically come in from the bottom.

But I am not sure if bringing in so many wires from the bottom is best.

I guess I am not the only one who thinks it should be neat and organized in there.

Please share any advice or links that are helpful

This is what I would like mine to look like

Since I am adding a Reliance transfer switch I will be adding a lot more wires and wire nuts.

It doesn't help that I have minimal electrical experience.

But, I am going to clean up the mess and I am going to add my new wires neatly.

Here is one of the better examples I have found and there are many good examples.

I picked this one because it shows extra wire neatly coiled up and tucked away. I am hesitant to cut all of my transfer switch wires off but I probably just need to get over that and cut the wires.

My neutrals and grounds go to both sides. I guess it doesn't matter but it looks like crap.

Another thing that concerns me is that my main breaker is at the bottom. The wires for everything I want to do typically come in from the bottom.

But I am not sure if bringing in so many wires from the bottom is best.

I guess I am not the only one who thinks it should be neat and organized in there.

Please share any advice or links that are helpful

This is what I would like mine to look like

Last edited: