Peltier heat pumps are horribly inefficient, modern dc permanent magnet refrigeration is far, far, far more efficient than Peltier heat pumps

Peltier run at *high voltage* is horribly inefficient.

Peltier run at 1-2V per 127 junction module

is efficient comparably so to refrigerant based compressor units.

CoP of 2-4 can be achieved which is comparable with compressor.

Edit: trying to provide actionable info..

Peltier are sold in grades based on their resistance. The rating is for how many amperes a single module can handle. For the 40x40mm modules the lowest efficiency rating is 3 ampere and the highest efficiency is 15 ampere.

15 ampere modules have ~1 ohm ac resistance

6 ampere modules have ~2 ohm

it just gets worse the lower ampere rating you go.

this means twice as much Joule heating if one sources TEC1-127

06 instead of TEC1-127

15 modules. Joule heating is inefficient compared to pumping heat.

not all peltier are the same. they can operate efficiently. happy to give more advice.

peltier element have a Max Voltage rating. Often 15.4V.

do not run the module at this voltage! run at 10-20% of Vmax. this is how to access Efficient Peltier Life.

The trick is that the modules can be stacked to sum the pumped heat. When run at 10-20% of Vmax the temperature difference across a single element is too low alone.

With ambient air 25C I’ve cooled water down to 7C and heated up to 70C using a stack of 20 units of TEC1-12715 modules arranged five side by side and four layer between two aluminum water blocks. It uses 80-100 W and it drives the peltier direct from the LFP battery. solid state heat pump

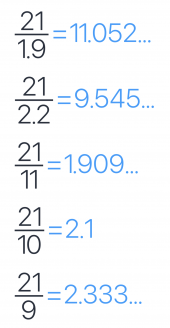

3S LFP battery. 9-11V. Using an H-bridge to drive all twenty peltier modules as one string. Electrically like a solar string it’s 5S4P wiring.

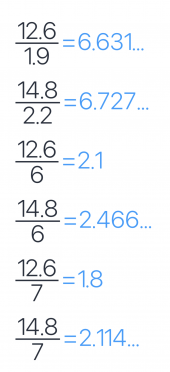

9/5 = 1.9 V per peltier module

11/5 = 2.2 V per peltier module.

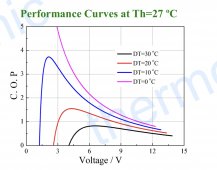

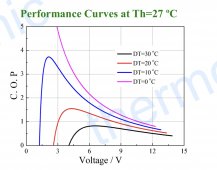

This is a coefficient of performance vs voltage graph for a TEC1-12715. Check the blue curve. It represents 10C delta temperature which is good for four layers. 4 layer x 10C = 40C max delta. Can get down to freezing if it’s ~30C ambient..

Anyways.. here’s a pic of the test setup:

the center display shows hot vs cold (primary vs secondary) side temp. 34C hot side 10C on cold side with 78W usage.

I was able to get that same side from as low as 7C all the way up to 70C. All while using <100W I think it’s fairly efficient. Haven’t evaluated CoP quantitatively yet. I expect CoP 1.5-3 depending on specific operating temperature.