You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

On Keeping LFP Warm

- Thread starter Horsefly

- Start date

Daddy Tanuki

Solar Wizard

Testing....14C seems like a high cut off for charging. Or is this for initial testing?

Is that ambient temperature or battery temperature?

Currently my BMS is set to stop all charge at 5°. I have my solar controllers set to stop at 14°

as I am in testing mode, and will keep that parameter until I have thoroughly tested the battery heater and feel comfortable with it. The battery heater should keep battery between 8 - 15°C I set the SCC point at 14°C for the time being as I am a three to four hour drive from my cabin during the week and as yet cannot remote monitor.

At worst, setting it at 14°c just means it cannot charge in the early morning hours for this time of the year.

Until I have directly observed the performance & behavior of my home brewed battery heater over several cycles and can show empirical proof of it following the predicted performance parameters, I am leaving nothing to chance. the idea here is to not be the guy whose batteries spectacularly die from a case of hopes and wishes.

once I have seen the battery warmer in action and am satisfied that it as well as the backup systems all work correctly I will remove the limit of the above mentioned 14° , and lower the Solar charge controllers to 8° and the BMS to 4°.

Horsefly

Solar Wizard

Sounds like a good set of experiments @ken morgan - before you commit for the winter!\Testing....

Currently my BMS is set to stop all charge at 5°. I have my solar controllers set to stop at 14°

as I am in testing mode, and will keep that parameter until I have thoroughly tested the battery heater and feel comfortable with it. The battery heater should keep battery between 8 - 15°C I set the SCC point at 14°C for the time being as I am a three to four hour drive from my cabin during the week and as yet cannot remote monitor.

At worst, setting it at 14°c just means it cannot charge in the early morning hours for this time of the year.

Until I have directly observed the performance & behavior of my home brewed battery heater over several cycles and can show empirical proof of it following the predicted performance parameters, I am leaving nothing to chance. the idea here is to not be the guy whose batteries spectacularly die from a case of hopes and wishes.

once I have seen the battery warmer in action and am satisfied that it as well as the backup systems all work correctly I will remove the limit of the above mentioned 14° , and lower the Solar charge controllers to 8° and the BMS to 4°.

I'm really curious about the 70V fault on your Magnum. Is that the magnum inverter? I think you said you have morningstar SCC's.

I have an all-Schneider system (with some regrets) but I get some odd faults that don't seem to match to reality. Strange....

Daddy Tanuki

Solar Wizard

yes the magnum inverter with its battery monitor system.Sounds like a good set of experiments @ken morgan - before you commit for the winter!\

I'm really curious about the 70V fault on your Magnum. Is that the magnum inverter? I think you said you have morningstar SCC's.

I have an all-Schneider system (with some regrets) but I get some odd faults that don't seem to match to reality. Strange....

To those interested: I couch the following as I think, I have no proof as of yet, but once I get a wifi hotspot to land line conversion figured out so that I can export data in real time and record data I will be able to possibly answer this better.

Two weeks ago I added 12 panels for an additional 2.4kw to the roof of the shop (total 6.4kw) and since I fired them up, once a day for the last eight days has shown a fault history where it is at high voltage surge of 69-71ish volts. To date it has occurred between 1330-1430 and I think it represents when the morningstar charge controllers disconnect due to high voltage.

the SCC is set as 54.4 charge, with a 54.1 VDC 1 hour absorb, and then it drops to a 54.0 float for 3 hours. no temp compensation, a high voltage disconnect of 56 volts, and a reconnect of 54.6 . it also has a setting called maximum regulation limit which honestly I don't understand the need for as it acts as a total cap on voltage output. I set that to 56 the same as the HVD.

it has not shut down the inverter, nor the BMS so it must be very brief and with no actual current to speak of. I know it has not shut down neither of the two for two reasons the Magnum does not show a shutdown in conjunction with the fault, and if the inverter or BMS did shut down then my split pack unit in the house would have shut down as well. (and not restarted.) (split pack is run on timer from 1000-1400 to dry out the house during the damp seasons).

I think the sudden termination by the SCC causes a brief transient surge. this happened once before that I noticed and at the time I had just suffered a BMS failure so I thought it might have something to do with that. (now I do not think so). it has happened daily since I added the extra panels.

one other thought that just entered my pea brain is that it could be when the a/c shuts down at 1400 hundred and the panels are cranking out juice to charge the pack and power the hotel loads including the a/c. possibly the shutdown of the a/c on timer might for a brief microsecond allow the SCC to race up to hit the maximum voltage regulation set point??? too many questions on this one and not having internet I cannot monitor and log them unless I am there. (and last time I was there is was heavily overcast, batteries hovered between 60-70 percent the entire time.)

anybody have an idea on if there are any routers that can take the wifi signal from a portable wifi hotspot and send it out a normal ethernet cable? the magnum and the tristars need an ethernet cable to a modem. I figure there has to be a way to do this. a pocket wifi would cost me like $30/month and I could then monitor my solar charge controllers, my inverter and even my bms via the internet...

Regards

Ken

Daddy Tanuki

Solar Wizard

also as I am sure someone will ask this... the Morningstar Solar charge controllers do not offer a temperature controlled charge parameter other than if you are using them for temp compensation on FLA or AGM batteries.

what I have is a separate temp controller that is wired in series with the Tristar's RTS. the temp controller opens the circuit on the RTS which then stops the SCC from charging until the RTS is reconnected.

Interrupting the circuit is a Morningstar approved way of preventing/stopping charging for any reason that you can build a circuit for. So in my case I use the same style temp controller as I use on the battery heater and I set the little temp controller to 14° and it will open the RTS circuit until the temp is above 14°. once it rises above the setpoint the SCC takes a few seconds to check its status and then it will start charging (or in the case of an interrupted charge, resume it).

many thanks to @Mcgivor for that tidbit about the TS MPPT and TS series SCC and the RTS.

what I have is a separate temp controller that is wired in series with the Tristar's RTS. the temp controller opens the circuit on the RTS which then stops the SCC from charging until the RTS is reconnected.

Interrupting the circuit is a Morningstar approved way of preventing/stopping charging for any reason that you can build a circuit for. So in my case I use the same style temp controller as I use on the battery heater and I set the little temp controller to 14° and it will open the RTS circuit until the temp is above 14°. once it rises above the setpoint the SCC takes a few seconds to check its status and then it will start charging (or in the case of an interrupted charge, resume it).

many thanks to @Mcgivor for that tidbit about the TS MPPT and TS series SCC and the RTS.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

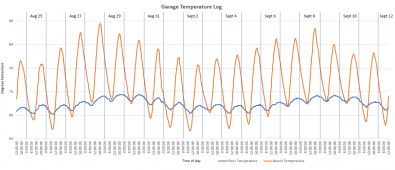

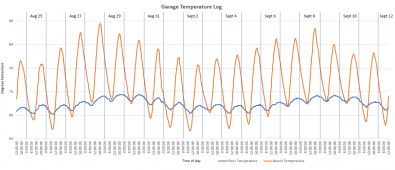

I have been considering an install of a large set of cells in an attached but un-insulated garage. They would be on the concrete slab floor of the garage. We rarely get freezing so I am not too concerned about that. (but I will have a low-temp disconnect). My big concern is it being too hot in the garage. Over the past few weeks I have been running an experiment with a logging thermometer covered with an insulating towel on the concrete floor and another logger on the bench above it (in the open air). I did not have a logger outside, but during this time the outside temp was into the 90s (F) on several days.

As I expected, the concrete slab has a tremendous buffering effect on the temperature. What I did not expect is that the temperature on the bench did not get higher.

This is enough data to convince me I wont' have a problem if I put an insulated box over the cells that are sitting on the concrete slab. However, I will keep the experiment going for two reasons: 1) We often get an extended hot spell in September and I want to see what happens. 2) Even though we only occasionally get overnight frost in the winter, I still want to see what happens in colder weather. As I get any interesting data I will post it here but I suspect there won't be anything worth posting till Jan or February and we have had a few cold spells. Even then, it does not get super cold here so it might not be very interesting.

As I expected, the concrete slab has a tremendous buffering effect on the temperature. What I did not expect is that the temperature on the bench did not get higher.

This is enough data to convince me I wont' have a problem if I put an insulated box over the cells that are sitting on the concrete slab. However, I will keep the experiment going for two reasons: 1) We often get an extended hot spell in September and I want to see what happens. 2) Even though we only occasionally get overnight frost in the winter, I still want to see what happens in colder weather. As I get any interesting data I will post it here but I suspect there won't be anything worth posting till Jan or February and we have had a few cold spells. Even then, it does not get super cold here so it might not be very interesting.

Last edited:

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

I had the same problem with my hunting cabin. When I leave, the battery is disconnected from everything and the BMS balance harness is unplugged. However, it is in the Mt Mountains were it can get extremely cold. I built a well insulated box and added this independent warmer to it and everything seemed to work just fine over the winter.So my issue is how we handle an LFP battery when the cabin is unoccupied for 5 months or so. If we have to carry them out for the winter, that could be a deal-breaker, and I may be stuck with AGM. In this case I'm not sure a small load periodically is an option.

Simple, Indipendent Battery Box Heater

To get the document, click on the orange button at the top of the page. This is a simple 20W battery Box heater that operates independently of the rest of your system. I use this for storing unused cells in a very cold climate, but it can be...

Sojourner1

Itinerant

Your concrete floor experiment is sort of like my setup in the 5th wheel front compartment. Thread in this section. https://diysolarforum.com/threads/12v-heating-pad.2468/

The metal floor during the colder seasons worked like a heat sync drawing heat from the cells cooling them off. I have no dought that during the cold months it will do the same, it might not be a problem if it doesn't get to extreme freezing. During the summer it probably helps as you see with the earth under the concrete keeping it cooler than the ambient air.

The metal floor during the colder seasons worked like a heat sync drawing heat from the cells cooling them off. I have no dought that during the cold months it will do the same, it might not be a problem if it doesn't get to extreme freezing. During the summer it probably helps as you see with the earth under the concrete keeping it cooler than the ambient air.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Yup..... the concrete slab temp is being buffered by the earth it is sitting on. It will be interesting to see what actually happens, but my expectation is that the floor temp won't get much below 60F even on the coldest nights. If it gets down to 50F I will be quite surprised. According to a google search, the typical temperature 15ft underground is 50-60F and usually varies only a few degrees year around. My slab is on top of the ground so it will vary more, but it will probably still stay in a relative narrow range.Your concrete floor experiment is sort of like my setup in the 5th wheel front compartment. Thread in this section. https://diysolarforum.com/threads/12v-heating-pad.2468/

The metal floor during the colder seasons worked like a heat sync drawing heat from the cells cooling them off. I have no dought that during the cold months it will do the same, it might not be a problem if it doesn't get to extreme freezing. During the summer it probably helps as you see with the earth under the concrete keeping it cooler than the ambient air.

It would be interesting if someone in a more sever-winter location did a similar experiment.

BTW: This is what I am using for my logging thermometer.

I am considering building something similar for my mountain cabin. Is it practical (based on real world experience) to build a super-insulated box that is only heated by panels and not drawing any current from the batteries? Because winters in the mountains get fewer good solar days, it seems to me that heating the battery box only during daylight hours of good solar might not be enough to keep the box warm above freezing for 3 or 4 days without solar.

In real world experience, how long can you keep a super insulated box interior above freezing if the ambient temps are -15F for several days on end?

My impression about reading most posts are based on conjecture and internet expertise, not real-world.

In real world experience, how long can you keep a super insulated box interior above freezing if the ambient temps are -15F for several days on end?

My impression about reading most posts are based on conjecture and internet expertise, not real-world.

Horsefly

Solar Wizard

In the first post in this thread (https://diysolarforum.com/threads/on-keeping-lfp-warm.17629/post-203007 - look at "Item 2") I showed the math of what the heat loss will be in the battery box. I've gone over it several times, I and am pretty sure it is correct. You should be able to insert your info and get an answer.I am considering building something similar for my mountain cabin. Is it practical (based on real world experience) to build a super-insulated box that is only heated by panels and not drawing any current from the batteries? Because winters in the mountains get fewer good solar days, it seems to me that heating the battery box only during daylight hours of good solar might not be enough to keep the box warm above freezing for 3 or 4 days without solar.

In real world experience, how long can you keep a super insulated box interior above freezing if the ambient temps are -15F for several days on end?

My impression about reading most posts are based on conjecture and internet expertise, not real-world.

"Super insulated" is hard in a simple battery box. I used the same thing as several others here used: 2" think XPS. XPS foam has an R-value of 5 for every inch of thickness, so putting 2" XPS on each side and on the top and bottom gave me R10. Plywood adds another R1.25 per inch of thickness. There have been some suggestions of some much more esoteric insulation, but they frankly don't sound practical. Adding 2" XPS makes your box 4" bigger in each dimension, which is quite a bit.

Your calcs and assumptions look solid to me. I guess I just need to try it and see. I'm more of a empirical than theoretical type when it comes to these DIY type efforts. I like to see real world projects.In the first post in this thread (https://diysolarforum.com/threads/on-keeping-lfp-warm.17629/post-203007 - look at "Item 2") I showed the math of what the heat loss will be in the battery box. I've gone over it several times, I and am pretty sure it is correct. You should be able to insert your info and get an answer.

"Super insulated" is hard in a simple battery box. I used the same thing as several others here used: 2" think XPS. XPS foam has an R-value of 5 for every inch of thickness, so putting 2" XPS on each side and on the top and bottom gave me R10. Plywood adds another R1.25 per inch of thickness. There have been some suggestions of some much more esoteric insulation, but they frankly don't sound practical. Adding 2" XPS makes your box 4" bigger in each dimension, which is quite a bit.

My "dream" plan is to bury my battery box 6 feet underground with 1 foot of insulation on all sides, hoping to get a little stability from the thermal mass of the surrounding soil. The lid would be more foam insulation. The battery pack would be mounted on metal frame that I can lift out. Because I have an excavator, this is practical. The big issue I foresee is moisture. I may just have to have a concrete box poured and insulate within that. My place gets down to -20F, but it's not heated except when I go there.

Horsefly

Solar Wizard

Ok, so this changes everything. If you can put your battery in what amounts to a root cellar with a well insulated top, you should be fine. You don't need (or want) to insulate the sides, as it is the ground / earth that will keep the room at a constant temperature. My guess is the temp will hold somewhere between 45°F and 55°F. You haven't said where your cabin is, but I assume it isn't sitting on permafrost.Your calcs and assumptions look solid to me. I guess I just need to try it and see. I'm more of a empirical than theoretical type when it comes to these DIY type efforts. I like to see real world projects.

My "dream" plan is to bury my battery box 6 feet underground with 1 foot of insulation on all sides, hoping to get a little stability from the thermal mass of the surrounding soil. The lid would be more foam insulation. The battery pack would be mounted on metal frame that I can lift out. Because I have an excavator, this is practical. The big issue I foresee is moisture. I may just have to have a concrete box poured and insulate within that. My place gets down to -20F, but it's not heated except when I go there.

My cabin is at 9,000 ft elevation in Colorado. For about 6 months of the year (from the end of November to late April / early May) there is no one there, and it is unheated. Our "solar room" is in the basement, which is partially below grade. I'm certain it gets below outside for zero several days in the winter. I had a temperature logger in the room last winter, but it was sitting between two large AGM batteries on a shelf that is about 18" above the slab. The temperature never got below 27°F all winter. This winter I'm logging again, but I have the sensor on the floor (concrete slab) this time.

I would have liked to have my batteries in a root cellar too, but the reason our cabin basement isn't more below grade is because the slab is mostly sitting on solid rock.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Do a search on "Earth Tubes". It is a way of bringing earth tempered air up to the battery

Hmm. yeah, I'm familiar with those. That was my original idea when I started contemplating going to the next level with solar. I sort of set it aside because heating with solar and resistive mats sounded simpler. Maybe I should return to that idea.Do a search on "Earth Tubes". It is a way of bringing earth tempered air up to the battery

My practical brain is telling me that I should just put a battery bank in my SUV, charge it at home in the winter and bring it up. And then cable my car to the cabin In winter. For typical 3-4 day weekends, this would work fine. I have to ski in, fire up my tractor and blow the snow out of a 1 mile long road (which takes little time with a big tractor and front snowblower!). I always have to bring my vehicle in, anyway. Ive heard of people using Prius for a battery bank..

Horsefly

Solar Wizard

You asked for some real-world experience. I documented the system I built to keep my LFP battery warm at our cabin here: https://diysolarforum.com/threads/horseflys-cabin-solar-lifepo4-upgrade.27472/Hmm. yeah, I'm familiar with those. That was my original idea when I started contemplating going to the next level with solar. I sort of set it aside because heating with solar and resistive mats sounded simpler. Maybe I should return to that idea.

My practical brain is telling me that I should just put a battery bank in my SUV, charge it at home in the winter and bring it up. And then cable my car to the cabin In winter. For typical 3-4 day weekends, this would work fine. I have to ski in, fire up my tractor and blow the snow out of a 1 mile long road (which takes little time with a big tractor and front snowblower!). I always have to bring my vehicle in, anyway. Ive heard of people using Prius for a battery bank..

I can't call it "experience" yet, because it is sitting in my garage here in the Denver area. I'm keeping it here over this winter to make sure it works as expected. I purchased temperature and voltage loggers to keep track of everything while it sits out on our patio in the cold. Assuming it works as designed, next spring I will be ripping out the AGMs and putting in the LFPs.

Some of what I did may be overkill: shut off if the voltage gets low, and the shut off if the aluminum plate gets to hot. If you leave those two items off, you just need one thermostat and some of the low-power heating pads.

It sounds like you have the "root cellar" approach available to you, so it probably doesn't matter any more.

I love it. I’ll be watching intently for the follow-up report next year!You asked for some real-world experience. I documented the system I built to keep my LFP battery warm at our cabin here: https://diysolarforum.com/threads/horseflys-cabin-solar-lifepo4-upgrade.27472/

I can't call it "experience" yet, because it is sitting in my garage here in the Denver area. I'm keeping it here over this winter to make sure it works as expected. I purchased temperature and voltage loggers to keep track of everything while it sits out on our patio in the cold. Assuming it works as designed, next spring I will be ripping out the AGMs and putting in the LFPs.

Some of what I did may be overkill: shut off if the voltage gets low, and the shut off if the aluminum plate gets to hot. If you leave those two items off, you just need one thermostat and some of the low-power heating pads.

It sounds like you have the "root cellar" approach available to you, so it probably doesn't matter any more.

Off all my options, I’m leaning to either:

1) Heated batteries with insulation (lazy option)

2) Some form of root cellar ( I can also store food!)

The root cellar is going to cost me 10k unless i do the work myself, but I’m too busy right now. Always time vs. money.

larryjackkelly

New Member

- Joined

- Oct 26, 2021

- Messages

- 1

AEROGEL (in some form) as insulation --I’ve looked / searched a bit and didn’t find anyone addressing this specifically, so I thought I would put down some thoughts and results of my computations and hopefully others will correct and/or contribute to a better picture.

We all know that LFP batteries need to be kept above 32°F/0°C for charging, and in fact they behave much better if kept closer to 50°F or more. There are numerous great threads here (and YouTube videos) of people building insulated boxes with heating pads. It got me thinking: Is there a way to know - or at least estimate - the specifics of what you NEED in a given installation?

That’s where my quest began a few days ago. I’m a retired engineer, so I started down the rabbit hole. The below is my initial take on calculating some requirements.

I think there are really two aspects to keeping cells warm in a battery box: Heating up the LFP pack, and the heat loss to the outside of the box.

Item 1: Heating an LFP pack

I realize there are lots of secondary items to consider here. For example: How much air / dead-space there is in the box around the pack. I’m happy to hear some thoughts about how to incorporate such items into a solution, but for now I’m going to concentrate on the heating of the pack.

After lots of Google searches, I found a source that said an LFP battery has a specific heat capacity of 1306 Joules / (kilogram x °C). (I can provide the source if someone really wants it, but it was a doctoral dissertation from the University of Waterloo) This is clearly a pretty inaccurate estimate, since any given battery is made up of varying proportions of several different materials. Each of those materials has a specific heat capacity, and the specific heat capacity of the cell depends on the proportions of each of the materials. The real number will be different for larger cells than it will be for smaller cells, and it will be different for aluminum case vs. plastic. However, for this rough estimate, lets use 1306. (Again - Please jump in with suggestions)

Now we can take the mass of the cells. For example, the aluminum-cased 280Ah cells weigh about 5.6kg each. A pack of 4 (for a 12.8V battery) would then weigh 4 x 5.6 = 22.4kg. Now if we multiply this weight by the specific heat capacity of 1306, we get:

22.4 x 1306 = 29,254.4 Joules per °C

A Watt is one Joule per second, so a Joule is one “Watt second”. To get to Watt-hours, we need to divide this number by 60 x 60 = 3600 seconds per hour:

29,254.4 / 3600 = 8.126 Wh per °C

So, ignoring all the inefficiencies that may be present, this means:

To heat one 4x280Ah pack one degree Celsius requires 8.126 watt-hours of energy

With no inefficiencies, you can raise the temperature of one pack from 32°F (0°C) to 50°F (10°C) in one hour if you use about 80W of heaters. You can use 40W of heaters and do the same in two hours. Because we know our box, heating pads, metal sheet etc. are not the perfect theoretical world, we could bump the number up by say 25% (?), so we could use 50W of heating pads, using around 4 amps continuously from our pack, until the thermostat turned them off in about two hours.

Thoughts?

Item 2: Heat loss from a battery box

We also know that the warm insides of our battery box will over time cool down to approach the temperature outside the box. How fast this happens depends on temperatures inside and outside the box, the material we use to build and insulate the box and how much it resists the transfer of heat, and the exposed area of this material. The degree something resists the transfer of heat is the “R-value” (or RSI-value in metric) that is used to rate insulation. All material has an R-value.

The imperial / American R-value has the units of

Square feet (area) x °F x hours / BTU

I find this much less handy to use than the metric RSI value, which has the units of

Square meters x °K / Watts (note that in this context °K is the same as °C)

Either one is really expressing how much a material resists the transfer of power (watts) between two different temps (°C) for a given area (square meters). You can convert an R value to an RSI value by dividing the R value by 5.678.

As an example, I’ve been planning out a battery box which is built from ¾” plywood on the outside, with the walls, top, and bottom lined with 2” XPS insulation. 2” XPS insulation has an R value of 10. Plywood has an R-value of about 1.25 per inch of thickness, so my ¾” plywood would have an R value of 0.75 x 1.25 = 0.9375. Combining the two layers of my box, the R value would be 10.9375. The RSI value would then be 10.9375 / 5.678 = 1.92629.

Now I need to add up the surface areas on the inside of the box, including the top, bottom, and all four sides (again, I’m ignoring some subtleties of the bottom losing less heat than the top, etc). Lets say my box had inside dimensions of 15” left-to-right x 12” front-to-back x 12” top-to-bottom. The total surface area would then be (2 x 12 x 12)(left and right side) + (2 x 12 x 15)(front and back) + (2 x 12 x 15)(top and bottom) for a total of about 1000 square inches.

1 inch is 0.0254 meters, so 1 sq inch = 0.0254 x 0.0254 = 0.00064516 square meters

Thus my 1000 sq inches of inside surface area is 0.64516 square meters.

Now let's assume that we want the inside of our box at 50°F (10°C), and outside the box it will be 32°F (0°C). The difference between the inside and the outside is then 10°C. Then it’s just algebra:

Rsi = sq meters x °C / Watts

Watts = sq meters x °C / Rsi

Watts = 0.64516 x 10 / 1.92629 = 3.3492

This means that a constant “leak” of 3.3492W of power is escaping the box. If the temperature difference is larger between the inside and outside of the box, the watts go up.

If I chose to use the cheaper, thinner 1” XPS (with an R value of 5 instead of 10), the watts escaping the box almost doubles.

Other Considerations?

My intent here was to define a way to at least estimate things. We don’t want to use heating pads that are too small, or the batteries will never really get / stay warm. On the other hand we don’t want them too big either. We should insulate our battery box, but how much?

I’ve admitted that what I’ve provided is theoretical, and in the real world there are other losses and inefficiencies. At the very least, what one builds should use these formulas only for a baseline, to which you add a fudge factor of +20% or +50% or ?

Hopefully I’ve got the formulas right, and hopefully they will help. What else can you guys think of to consider?

futureproof

New Member

- Joined

- Aug 13, 2021

- Messages

- 30

Unless I am missing something, this is not an issue. If you are just storing your batteries at the cabin-site without using them or charging them, they are fine just sitting there (supposedly down to about -40º F). Not really a risk to go with LifePO4... just bring them down to about 50-70% or something before you leave for the Winter and disconnect the solar panels. They can sit at 2/3 charge with no parasitic drain, and then in the Spring just charge them up. Only issue will be in the Spring when make it back up you will need to keep them warm still if you want to use and charge. I know in the spring at 9000' it is still going to be a challenge to use the batteries unless they are indoors or heated.What got me started on this is a similar situation. Our off-grid cabin is at 9,000 ft elevation in the mountains of Colorado, with 30 miles or so of dirt / unmaintained roads. We pretty much shut down the place in mid-November and don't get back up there until late-April or mid-May. In between our batteries (which currently are lead-acid, but aiming for LFP) are sitting in the basement of an unheated structure.

The current setup has four big lead-acid AGM batteries. The charge controller stays on all winter, and the panels are seldom covered with snow for more than a couple of days. Lead-acid batteries do fine down to something like -70°F, so its all been fine. If not for the inevitable decline of the lead-acid batteries, we could probably stay with it for many years.

I've got a temperature logger capturing and logging the temps on the battery shelf every hour all winter long. I predict there will be a few days that don't get above 0°F. In the end I may decide it is just too risky to go to LFP.

Even better, just keep your panels connected to your AGM batteries (or 1-2 of them) with a very low Watt heater that heats the battery space. That way you are still using the solar energy being generated but not putting it into the lithium batteries that won't need it anyway.

Similar threads

- Replies

- 4

- Views

- 209

- Replies

- 2

- Views

- 556

- Replies

- 12

- Views

- 282

- Replies

- 26

- Views

- 862