You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

~100kwh for 24/7 off grid home

- Thread starter tanoshimini

- Start date

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

Awesome build!

My 2 cents after reading. You said the packs you are using are 14s to start with. How did you end up with 16s?

Those server rack batteries with the 2kwh capacity remaining, most likely have been cycled many times. Might not have a lot of cycles left. Good you oversized the battery to lessen the DOD-cycles. I think their original capacity is double that. David poz did a video on them.

I truly understand trying to do things cheap. I purchased low mileage full EV packs. All of mine are under 25k miles. They tested really close to new. You have to take apart the full packs which takes a bit of work but would have been no problem for you. 16s and 12s packs come in the particular EV full packs I used. I needed the 16s packs and sold the 12s so hardly paid anything for the 16s I’m using.

My 2 cents after reading. You said the packs you are using are 14s to start with. How did you end up with 16s?

Those server rack batteries with the 2kwh capacity remaining, most likely have been cycled many times. Might not have a lot of cycles left. Good you oversized the battery to lessen the DOD-cycles. I think their original capacity is double that. David poz did a video on them.

I truly understand trying to do things cheap. I purchased low mileage full EV packs. All of mine are under 25k miles. They tested really close to new. You have to take apart the full packs which takes a bit of work but would have been no problem for you. 16s and 12s packs come in the particular EV full packs I used. I needed the 16s packs and sold the 12s so hardly paid anything for the 16s I’m using.

tanoshimini

Solar Enthusiast

- Joined

- Mar 28, 2021

- Messages

- 110

Awesome build!

My 2 cents after reading. You said the packs you are using are 14s to start with. How did you end up with 16s?

Each rack battery module contains 14 cells, in a 14S string. I took them apart and reorganized them as 7p2s. I then I took 8 of those reconfigured rack modules to make a very large 7p16s battery.

Those server rack batteries with the 2kwh capacity remaining, most likely have been cycled many times.

I'm very sure they have. I tested a large fraction of the units and they seem to fall between 2.2-2.4kwh, remaining capacity.

The original specs were 3.2kwh per rack unit, near as I can tell.Might not have a lot of cycles left. Good you oversized the battery to lessen the DOD-cycles. I think their original capacity is double that.

Sounds pretty cool! You should take some pictures and post them! I enjoy seeing all of the different ways that these problems are being solved here. What did the cost per kwh work out to for your batteries, with all the reconfiguration/BMS/wiring/enclosure/etc.?David poz did a video on them.

I truly understand trying to do things cheap. I purchased low mileage full EV packs. All of mine are under 25k miles. They tested really close to new. You have to take apart the full packs which takes a bit of work but would have been no problem for you. 16s and 12s packs come in the particular EV full packs I used. I needed the 16s packs and sold the 12s so hardly paid anything for the 16s I’m using.

tanoshimini

Solar Enthusiast

- Joined

- Mar 28, 2021

- Messages

- 110

Also, the inverter that I'm using is rated to 66v, so using 16s not only fills out the box nicely, but allows me to run at a slightly higher voltage (which decreases resistive losses and cuts the amps that I'd push over the wire by ~9% for the same amount of power.)You said the packs you are using are 14s to start with. How did you end up with 16s?

Alternatively, I could have left it at 14s... Gone with one less rack-module, and fitted each box with a multiplus-ii in it's place. This would have kept the DC wiring entirely within the box, and been more redundant/modular at the cost of some extra standby power and some $$$.

SalckwareRobert

New Member

- Joined

- May 28, 2020

- Messages

- 35

Good disguise. Who would want to steal a box of hyundai car parts. 20kw, i'm drooling.......

I'm not putting PV on roof till I figure out self cleaning system for them. Have several ideas for tilt, and angle on roof already. I didn't design the roof for the wind loads 30 2 sided panels sticking out four feet over 1st floor porch metal roof to use the light bouncing off it would generate. But It's not like I don't have room to put up a farm on the ground. Plus cover with foil, and you can use them to reflect sun and blind the attack helicopter pilot with a huge virtual parabolic mirror.

The only reason I want to order a pallet of ammo, is to watch poor UPS guy have to hump a hundred thousand rounds up the driveway to the house.

Didn't think they would ship a +1500lb pallet of panels.

I'm not putting PV on roof till I figure out self cleaning system for them. Have several ideas for tilt, and angle on roof already. I didn't design the roof for the wind loads 30 2 sided panels sticking out four feet over 1st floor porch metal roof to use the light bouncing off it would generate. But It's not like I don't have room to put up a farm on the ground. Plus cover with foil, and you can use them to reflect sun and blind the attack helicopter pilot with a huge virtual parabolic mirror.

The only reason I want to order a pallet of ammo, is to watch poor UPS guy have to hump a hundred thousand rounds up the driveway to the house.

Didn't think they would ship a +1500lb pallet of panels.

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

I purchased one of the 2017 8k miles full packs for $2200. It was 18.4kwh. It comes with 7 battery packs in the full pack. I sell all of the four 12s batteries from that pack for $2100 total. Which is less than anyone else sells them for. I keep the three 16s packs from the full pack. The three 16s packs are 3.1kwh each 9.3kwh total that I keep from each full EV packs. I’ve done this twice. I now have 18.6 kWh, that’s six 16s packs in parallel. That’s $200 I paid between the two packs. That’s $10.75 per kWh.Each rack battery module contains 14 cells, in a 14S string. I took them apart and reorganized them as 7p2s. I then I took 8 of those reconfigured rack modules to make a very large 7p16s battery.

I'm very sure they have. I tested a large fraction of the units and they seem to fall between 2.2-2.4kwh, remaining capacity.

The original specs were 3.2kwh per rack unit, near as I can tell.

Sounds pretty cool! You should take some pictures and post them! I enjoy seeing all of the different ways that these problems are being solved here. What did the cost per kwh work out to for your batteries, with all the reconfiguration/BMS/wiring/enclosure/etc.?

My bms was $150. I built the enclosure from sheet metal. It cost roughly $150. Wiring, power distribution blocks etc might be another $75. With all that it was $31 per kWh.

Reason I only have 18.6kwh is that I’m not offgrid. My main inverters are limiting grid tie inverters that only allow the inverters to supply as much as the loads need. The grid ties use batteries. The 18.6kwh keeps the grid tie inverters running all year 24/7 supplying all of my homes loads except in the summer due to how hot it is in southern Tennessee. A/C is a killer. I also have a 4kw offgrid inverter to power essential loads during the rare power outage. It uses the same battery.

In the pic you asked for the bms is only wired to three batteries. Bms is currently wired to all six batteries which made a bigger red rats nest

Attachments

Last edited:

Thermodynamical

:̸̢̤̩̹͙̞̲̫̓̽

- Joined

- May 26, 2020

- Messages

- 36

This is an amazing thread. Thank you for sharing!

This is a very interesting thread. Kudos to the OP for all his hard work. Just a couple of comments, mainly aimed at others who might be contemplating this type of setup, or even parts of it. I too have been looking at job site boxes because they are relatively inexpensive, and are pretty sturdy. I question his comments that they are designed to live outside. They certainly are outside a lot, but most people I know end up storing them indoors when not in use. Many of them never get removed from a truck or trailer due to the weight. First, keep in mind that there is going to be significant condensation, and eventually rust. Only time will tell if his efforts to insulate the boxes, and provide some heating mats will take care of that.

If I was building to the extent he has, I'd incorporate PEX tubing into the slab, and heat a small building with hot water, preferably from a solar panel. It is not difficult. You don't need a lot of heat to keep things dry, and at the right temperature. I've spent a huge amount of time playing with shipping container ideas, but they have gotten very expensive, and a lot of work still has to be done to get them insulated. After penciling out the costs locally, I chose to pour a heated slab, and am building a small utility shed. 8' x 16', with 9' ceilings at the ridge. But I'm in town, not in Maine. I'm envious.....

Each of my solar panels will produce an average of about 29k BTU per day. With a heated shed, you don't need the job boxes, you just need strong shelving. Of course, that is not as resistant to theft. For my boiler system, I have a Lithium Titanate 7.5kw system for emergency backup.

Another comment, one that I struggle with: maximum battery voltage. I've spoken with tech services at most of the major companies over the last couple of years. When asked about the top acceptable voltage, most of them told me that anything over 60v would cause a lot of over voltage tripping. I too have Victron, but am reconfiguring some of my batteries for 14s, rather than 16s. (NMC) I have no way of qualifying that statement any further, and am not trying to start up a discussion debating that. I'm just telling everyone what techs told me. I personally like the idea of higher voltage, and would rather run in that fashion, but there are few choices that can handle over 60v. (Here in the USA)

I applaud his work. A lot of effort and thought went into it. Onward and upward!

If I was building to the extent he has, I'd incorporate PEX tubing into the slab, and heat a small building with hot water, preferably from a solar panel. It is not difficult. You don't need a lot of heat to keep things dry, and at the right temperature. I've spent a huge amount of time playing with shipping container ideas, but they have gotten very expensive, and a lot of work still has to be done to get them insulated. After penciling out the costs locally, I chose to pour a heated slab, and am building a small utility shed. 8' x 16', with 9' ceilings at the ridge. But I'm in town, not in Maine. I'm envious.....

Each of my solar panels will produce an average of about 29k BTU per day. With a heated shed, you don't need the job boxes, you just need strong shelving. Of course, that is not as resistant to theft. For my boiler system, I have a Lithium Titanate 7.5kw system for emergency backup.

Another comment, one that I struggle with: maximum battery voltage. I've spoken with tech services at most of the major companies over the last couple of years. When asked about the top acceptable voltage, most of them told me that anything over 60v would cause a lot of over voltage tripping. I too have Victron, but am reconfiguring some of my batteries for 14s, rather than 16s. (NMC) I have no way of qualifying that statement any further, and am not trying to start up a discussion debating that. I'm just telling everyone what techs told me. I personally like the idea of higher voltage, and would rather run in that fashion, but there are few choices that can handle over 60v. (Here in the USA)

I applaud his work. A lot of effort and thought went into it. Onward and upward!

how the hell do you use 30 kwh in a day? Do you let a hairdryer fight a fridge 24/7?According to the link you shared, your consumption is on par with the average American household.

10649 kWh/year ÷ 365 days/year = 29.18 kWh/day

Seriously tho.. 30kwh that is 1800w constant power draw during 16 hours. I assume the average american household dont need power to sleep at night unless its in northern part during winter

luckielab

New Member

- Joined

- Nov 26, 2020

- Messages

- 91

Where I live (coastal mid-Atlantic), air conditioning to remove humidity and heat uses a ton of kwh.how the hell do you use 30 kwh in a day? Do you let a hairdryer fight a fridge 24/7?

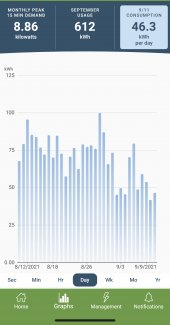

46.3 yesterday.

Attachments

oh damn :OWhere I live (coastal mid-Atlantic), air conditioning to remove humidity and heat uses a ton of kwh.

46.3 yesterday.

I can use 15 per hour with both A/C running to cool the house on low cost electricity at night and charge my car overnight.how the hell do you use 30 kwh in a day? Do you let a hairdryer fight a fridge 24/7?

Have spiked to 100 kWh in 24hrs depending on conditions.

crossy

Solar Addict

Nice! Very, very nice!! Like others I'm a bit embarrased by the arrangements for our storage.

On the overall consumption front, we are swallowing between 40 and 60kWh per day here in sunny Thailand, the majority of which is actually keeping Madam's koi in air and UV, the pool pump uses rather too much too.

Hopefully once we get the grandkids back to school (they're remote learning at present and using the A/C 24/7) we might get down to something sensible.

On the overall consumption front, we are swallowing between 40 and 60kWh per day here in sunny Thailand, the majority of which is actually keeping Madam's koi in air and UV, the pool pump uses rather too much too.

Hopefully once we get the grandkids back to school (they're remote learning at present and using the A/C 24/7) we might get down to something sensible.

Last edited:

wattmatters

Solar Wizard

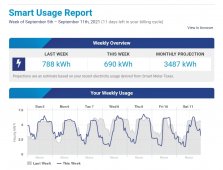

Homes which are all electric will consume more electricity than homes which use gas for heating, water heating and cooking. And increasingly homes will be charging EVs as well to add to that.how the hell do you use 30 kwh in a day?

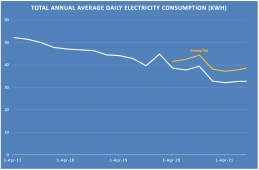

Our home electrical energy consumption averages 32kWh/day. We have done a bunch of stuff to bring that down over the past five years, as energy not consumed is the cheapest.

We need a lot of reverse cycle aircon for our hot humid Summer and it's also our heating in Winter. Hot water is electric resistance storage tank.

This is how out rolling average annual consumption has tracked since we moved into our home:

At the start of 2020 we added a secondary dwelling, so that total energy consumption is shown with and without the extra dwelling. Extra dwelling uses ~5kWh/day.

We've had some big days, biggest was ~144kWh. Family visiting, hot humid Summer day with 3 large aircon systems going for long periods. But overall we have managed to reduce our home consumption by 20kWh/day through a variety of strategies. We have more to do, especially to improve the abysmal thermal performance of our 1970s build home. How much further this can be driven down I can't say but I'm working on it bit by bit.

tanoshimini

Solar Enthusiast

- Joined

- Mar 28, 2021

- Messages

- 110

This is a very interesting thread. Kudos to the OP for all his hard work. Just a couple of comments, mainly aimed at others who might be contemplating this type of setup, or even parts of it. I too have been looking at job site boxes because they are relatively inexpensive, and are pretty sturdy. I question his comments that they are designed to live outside. They certainly are outside a lot, but most people I know end up storing them indoors when not in use. Many of them never get removed from a truck or trailer due to the weight. First, keep in mind that there is going to be significant condensation, and eventually rust. Only time will tell if his efforts to insulate the boxes, and provide some heating mats will take care of that.

If I was building to the extent he has, I'd incorporate PEX tubing into the slab, and heat a small building with hot water, preferably from a solar panel. It is not difficult. You don't need a lot of heat to keep things dry, and at the right temperature. I've spent a huge amount of time playing with shipping container ideas, but they have gotten very expensive, and a lot of work still has to be done to get them insulated. After penciling out the costs locally, I chose to pour a heated slab, and am building a small utility shed. 8' x 16', with 9' ceilings at the ridge. But I'm in town, not in Maine. I'm envious.....

My situation is, well, a little weird. We bought a 100+ acre chunk of raw forest, that had as it’s only existing infrastructure a stubby stretch of 150’ of driveway. If we were retrofitting batteries into a place that already had some existing buildings, amenities and such, I’m pretty sure that I’d be doing exactly as you suggest. It’d make more sense. We didn’t know exactly where we were going to build at first, so we needed to be able to use the batteries (and move them around) well before we’d have the ability to bring in a cement truck, so insulated job boxes made more sense for us. Once we decided on a site and had built some driveway, we gave them a slightly more permanent home. We’ve setup a 20x12 ShelterLogic as a workshop on our build site (down ~950’ of driveway), and have it wired up with lights, outlets and it runs our (220v) well pump. We keep it charged right now with a really simple 2x4 ground mount, and three 375w panels, though we started off by using a little generator.

Next year, we plan to put up a fairly large permanent workshop. The batteries will be moved into or adjacent to the building (but under a roof) at that time. We don’t anticipate leaving them fully exposed to the elements beyond this year. So far, so good, though. Nothing has gotten wet, dirty, or infested by bugs or furry things to date.

Each of my solar panels will produce an average of about 29k BTU per day. With a heated shed, you don't need the job boxes, you just need strong shelving. Of course, that is not as resistant to theft. For my boiler system, I have a Lithium Titanate 7.5kw system for emergency backup.

Righteous! LTO batteries make a lot of sense for emergencies, since they can be left unheated and still be used. We’ll be looking into something similar for our emergency system.

Another comment, one that I struggle with: maximum battery voltage. I've spoken with tech services at most of the major companies over the last couple of years. When asked about the top acceptable voltage, most of them told me that anything over 60v would cause a lot of over voltage tripping. I too have Victron, but am reconfiguring some of my batteries for 14s, rather than 16s. (NMC) I have no way of qualifying that statement any further, and am not trying to start up a discussion debating that. I'm just telling everyone what techs told me. I personally like the idea of higher voltage, and would rather run in that fashion, but there are few choices that can handle over 60v. (Here in the USA)

We’ve been running our Quattro on 16s (NMC) @ 60v nominal without issue all year long. “Full charge” for us is 64v (4.0v/cell). We monitor the Quattro daily and haven‘t had a single warning / error / trip. We’re on the latest firmware, and haven’t done anything to the unit that the VictronConnect app won’t let us do. So, one data point.

We’re still building the house, so we’re mostly running large power tools, pressure washers, lights and the well pump off the system right now. Everything has been functioning well and without complaint. If past is prologue, I don’t see any significant problems cropping up as we add more panels and more loads. We’ll see!

Thanks! I‘d love to hear more about your setup.I applaud his work. A lot of effort and thought went into it. Onward and upward!

Shale MacGregor

Solar Enthusiast

- Joined

- Sep 5, 2021

- Messages

- 641

hrm, guess I shouldnt mention that we use 100 kwh a dayhow the hell do you use 30 kwh in a day? Do you let a hairdryer fight a fridge 24/7?

Seriously tho.. 30kwh that is 1800w constant power draw during 16 hours. I assume the average american household dont need power to sleep at night unless its in northern part during winter

Similar threads

- Replies

- 3

- Views

- 266

- Replies

- 11

- Views

- 326

- Replies

- 1

- Views

- 150