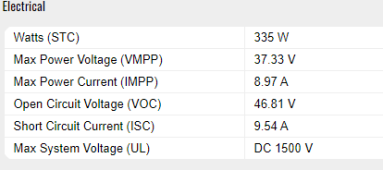

I have 8 panels with the specs shown above. I thought I needed a 100amp SCC to charge my batteries. I have 2x 100ah in series for 24V. I used an amp calculator with 335w, 46V, 8 Panels and it say it is 60 amp. Not sure if that is correct. The DC output side is 24v so does that means I need 100 amp output? The SCC seems to be describing input voltage not output voltage, see link. Is the 60A rating for both or just input?

This calculator is giving me 71 amp to SCC

Solar Charge Controller Calculator

Last edited: