Since I am such a NEWBIE, please help give me confidence this won't blow up on me, I welcome your thoughts and suggestions.

This system will be in a minivan.

206ah battery

Cables 2/0. 4' round trip to/from busbars.

Fuse 225-amp battery mounted thermal fuse block.

Inverter 220 watt.

Cables 2/0. 4' round trip to/from busbars.

Fuse 200-amp mounted next to positive bus bar.

12v vehicle battery positive terminal to Victron 12/12-30

Cable #6, 4' long

Fuse 60-amp at 12v battery

Cables #6 to/from Victron. 14' round trip to/from busbars

Fuse 60-amp at positive bus bar.

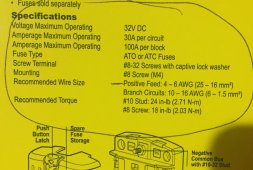

DC fuse box, rated for 100-amp max

Cables #2. 4' round trip to/from bus bars

Fuse 125-amp at positive bus bar.

This system will be in a minivan.

206ah battery

Cables 2/0. 4' round trip to/from busbars.

Fuse 225-amp battery mounted thermal fuse block.

Inverter 220 watt.

Cables 2/0. 4' round trip to/from busbars.

Fuse 200-amp mounted next to positive bus bar.

12v vehicle battery positive terminal to Victron 12/12-30

Cable #6, 4' long

Fuse 60-amp at 12v battery

Cables #6 to/from Victron. 14' round trip to/from busbars

Fuse 60-amp at positive bus bar.

DC fuse box, rated for 100-amp max

Cables #2. 4' round trip to/from bus bars

Fuse 125-amp at positive bus bar.