Hi All,

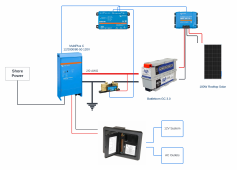

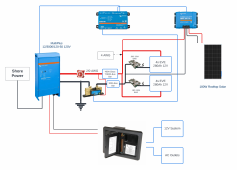

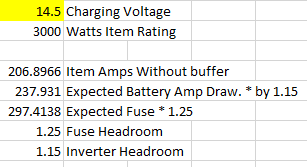

Just starting my build design for our new Airstream Basecamp 20x. The trailer already has 180W of solar on it but I want to convert from AGM to LiFePO4... See attached diagram as my starting point. I think I still need to add some fuses for protection. I plan on putting in an inverter charger to be able to use the AC outlets from the battery. I also plan on connecting the inverter output into the existing converter charger. Should I disconnect the converter portion of the converter charger since it will always see AC power and convert? Anything else major that I am missing?

Just starting my build design for our new Airstream Basecamp 20x. The trailer already has 180W of solar on it but I want to convert from AGM to LiFePO4... See attached diagram as my starting point. I think I still need to add some fuses for protection. I plan on putting in an inverter charger to be able to use the AC outlets from the battery. I also plan on connecting the inverter output into the existing converter charger. Should I disconnect the converter portion of the converter charger since it will always see AC power and convert? Anything else major that I am missing?