eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

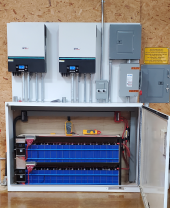

same, installing my system in my RV to power the house... going to be a freaking huge battery for an RV, but hey - so I get double purpose out of it.Fire protection was another reason I went with a trailer mounted system. Everything is outside, on a gravel driveway, separate from the house.

When I'm camping I don't need power at home