DipstickDash

New Member

- Joined

- Nov 30, 2021

- Messages

- 15

Hi all.

I know it's not the prettiest build. It's my first time.

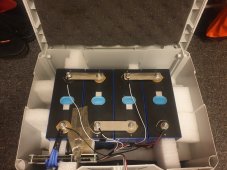

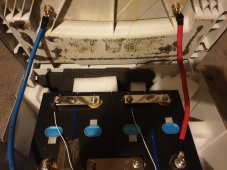

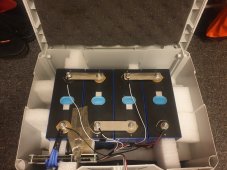

I have x4 280ah EVE cells with QUCC 120A BMS.

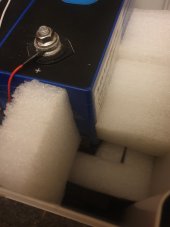

I found a decent sized heavy duty transport box for the battery to sit in but there was space around the side of the battery.

So I've added polystyrene to stop the battery from moving and rattling. My question is is this safe?

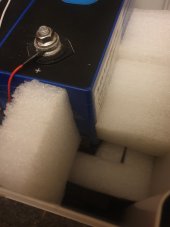

There is also foam already built on to the lid of the box. It's directly above the terminals almost touching, probably not ideal. I'm think I should remove the top foam add some holes at the tops for ventilation. Also connect & add some M6 post terminals outside the case.

Thoughts?

I know it's not the prettiest build. It's my first time.

I have x4 280ah EVE cells with QUCC 120A BMS.

I found a decent sized heavy duty transport box for the battery to sit in but there was space around the side of the battery.

So I've added polystyrene to stop the battery from moving and rattling. My question is is this safe?

There is also foam already built on to the lid of the box. It's directly above the terminals almost touching, probably not ideal. I'm think I should remove the top foam add some holes at the tops for ventilation. Also connect & add some M6 post terminals outside the case.

Thoughts?