You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

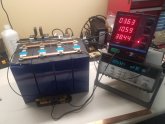

12V 280Ah LiFePo4 battery Build and Test

- Thread starter Haugen

- Start date

Still waiting for my BMS and my test load. I ordered them 4/30 and 5/2 respectively. AliExpress says they left China on 5/21 and 6/4 by air. That's the slowest airplane I've ever known!

My 40lb batteries got here faster by sea.

Tomorrow is the latest extended date that they gave me. I have 3 orders that I am going to file disputes on.

My 40lb batteries got here faster by sea.

Tomorrow is the latest extended date that they gave me. I have 3 orders that I am going to file disputes on.

I used 1" x .185" copper bar stock for my bus bars, and 20 mm stainless studs. 20 mm seemed to be the sweet spot for me for the thickness of the bus bar and the BMS leads. I put some no-ox grease on the terminals before I bolted everything down. Then put heat tape over the terminals and connections. So far so good.Copper bus bar material came in today!

If I go with this, there will be no questions about capacity should I decide to add another 4 cells.

I'll probably need longer bolts!

View attachment 16040View attachment 16038

mapguy525

Solar Enthusiast

McMaster Carr has aluminum threaded rod on their website. They may have aluminum screws, too.It took a few days with only 10A charge capacity to get the cells to full charge for a top balance.

I'm now in a holding pattern waiting for the BMS to arrive.

In the meantime, I have ordered some copper and aluminum bar stock to make some improved bus bars. I bought both because I'm still debating in my head and researching which is the lesser of the two evils. Lower conductivity of the aluminum, or the galvanic reaction between copper and aluminum.

The interesting thing is that the bolts that came with the cells are brass to throw in another galvanic element. I'm leaning towards heavier aluminum bus bars as long as I can find 6mm aluminum screws to hold it all together.

Have you considered Dacromet coated steel fasteners?

https://www.mcmaster.com/stud-bolts/aluminum-threaded-rods/

Last edited:

Unfortunately, McMaster Carr has only SAE threaded rod in aluminum. I switched to metric and they only have steel and brass.

The batteries are M6-1 threads.

I'm finding some aluminum hex head bolts and cap screws on eBay. Depending on the length, they are about $15 for 4 of them. I guess $3.25 isn't too bad.

The trick is to find some that ship from the US. I don't want to wait for months on bolts.

I'll check my local Ace Hardware first. They carry lots of odd stuff.

The batteries are M6-1 threads.

I'm finding some aluminum hex head bolts and cap screws on eBay. Depending on the length, they are about $15 for 4 of them. I guess $3.25 isn't too bad.

The trick is to find some that ship from the US. I don't want to wait for months on bolts.

I'll check my local Ace Hardware first. They carry lots of odd stuff.

John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

What is the problem with zinc?Whatever I use, I will definitely put connector lubricant on it to reduce the available oxygen to cause corrosion.

I read the contents of Noalox and I'm not a fan because it has zinc suspended in it.

I have a can of SuperCorrA that does an amazing job of protecting connectors.

I think they are worried about electrolysis. I have had lithium batteries in place for over a year now with mixed metals holding them together without any issue at all. This could be a problem 10 years from now but for now it is not. So I use zinc boltsWhat is the problem with zinc?

AE4KR

Ham Radio Tinkerer

I'm finding some aluminum hex head bolts and cap screws on eBay...

How much torque is needed on these bolts? I'd worry about stretching aluminum bolts, especially mystery bolts from ebay, and terminals getting loose as a result. What about using stainless bolts with PTFE shoulder washers to keep the bolts from contacting the terminals or bus bars?

Ampster

Renewable Energy Hobbyist

These holes are so shallow I want every thread available to spread the torque. I go to the bottom and back out 1/4 turn and hold the stud with a hex wrench as I tighten the nut.

I did not think I could optimize that depth with bolts.

I did not think I could optimize that depth with bolts.

Ampster

Renewable Energy Hobbyist

It is in the specs as a not to exceed number. I am using Nord lock washers.How much torque is needed on these bolts?

Metalophile

Analytical Chemist

Are the threads in the terminals M6? I found someone selling these cells on Ebay and the spec sheet he has says they are M4, but that seems tiny for such large cells.

From what I understand the early versions of these batteries had M4 terminal holes, but the latest ones are M6. My batch was ordered in early April and they’re M6. The latest spec sheet says M6 too. (Version E). Go with M6 terminals.Are the threads in the terminals M6? I found someone selling these cells on Ebay and the spec sheet he has says they are M4, but that seems tiny for such large cells.

That's the rub isn't it. Its the conductivity between the aluminum terminal and the copper wire that is the most important.How much torque is needed on these bolts? I'd worry about stretching aluminum bolts, especially mystery bolts from ebay, and terminals getting loose as a result. What about using stainless bolts with PTFE shoulder washers to keep the bolts from contacting the terminals or bus bars?

How you make that transition is very important. If you put the dissimilar metals together down in a threaded hole, I think you are asking for trouble. Your threads are eventually going to corrode away and you have no way to connect to your power source. To me, it makes much more sense to make that transition somewhere that can be monitored, inspected, and maintained.

Ampster

Renewable Energy Hobbyist

My environment will be low humidity so hopefully the threads last 10 years. I have several fall backs if they don't. Retap the hole to the next size up or insert helicoils. I will also be happy if my cells last 10 years.Your threads are eventually going to corrode away and you have no way to connect to your power source.

I reached the end of the rope on my BMS. July 1 was the last date they gave me for delivery. The tracking numbers still say "departed original country" after having been "received by airline".

I filed a dispute with AliExpress. I don't know if they will eventually be delivered, but I now need to find another BMS. I just hate that I have been waiting 2 months already and have to start over.

Does anyone have a link to the BMS they bought that delivered quickly?

I filed a dispute with AliExpress. I don't know if they will eventually be delivered, but I now need to find another BMS. I just hate that I have been waiting 2 months already and have to start over.

Does anyone have a link to the BMS they bought that delivered quickly?

@Craig On this forum was selling some Chargery BMSs a while back. Check with him to see if he has any left. I personally use the Chargery BMS8T and have been very satisfied with it.I reached the end of the rope on my BMS. July 1 was the last date they gave me for delivery. The tracking numbers still say "departed original country" after having been "received by airline".

I filed a dispute with AliExpress. I don't know if they will eventually be delivered, but I now need to find another BMS. I just hate that I have been waiting 2 months already and have to start over.

Does anyone have a link to the BMS they bought that delivered quickly?

Metalophile

Analytical Chemist

What BMS would be good for a 4S pack of these? I assume the max discharge rate would be around 280A, although if I build a pack I would use it to power a 2Kw inverter so I don't see myself pulling more than ~170A continuous out of this pack. Can 3x 60A BMS be used in parallel? Or should I just spring for a 200A BMS?

The BMS I ordered was a 120A. My needs are pretty simple for this project. It's a modern mini camper with all LED lights and a Dometic fridge that doesn't draw a lot of power. It's too small to consider running the air without shore power or generator.What BMS would be good for a 4S pack of these? I assume the max discharge rate would be around 280A, although if I build a pack I would use it to power a 2Kw inverter so I don't see myself pulling more than ~170A continuous out of this pack. Can 3x 60A BMS be used in parallel? Or should I just spring for a 200A BMS?

200A and 300A BMSs are showing up. You can talk to the sellers and ask if they will add FETs and wire size to increase current.

Similar threads

- Replies

- 1

- Views

- 163

- Replies

- 0

- Views

- 114

- Replies

- 18

- Views

- 431

- Replies

- 20

- Views

- 1K