Afternoon folks. Thought I would post up a pack I am building for our van to replace a 510AH lead pack that's about done. Its nominal 12V with 8x 280Ah cells.

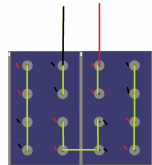

Here is the battery box design. Its a section view for obvious reasons, not actually cut down the side. Design is intended to drop through a hole in the floor to minimize interior space loss. Compression plates on either end with 1/4" threaded rod to connect them. Not sure how I will tie the batteries down, but thinking about nylon straps, but a bolt and hook design may also work. The plan is to order some laser cut steel sheet (16 gauge?) and weld it up.

The cells are EVE 280AH type from the Xuba seller. Should be getting those next month.

BMS is still in flux, but strongly considering a Orion Jr, and Gigivac or Blue Sea Latching relay for disconnect.

Our van is our home for years at a time when we travel various countries, so we are pretty serious about our comfort and power systems. This pack combined with a custom mini split will let us sleep in comfort when the heat index is triple digits F. A long thread on the van is over here.

Looking at making custom bus bars from 2/0 copper braid. I would be soldering solid copper pads for each terminal connection.

https://www.mcmaster.com/69925K43/

The box will be insulated with 0.5 or 0.75" XPS foam. Looking at a 65W 12v heating pad for the bottom.

I have an existing outback inverter, solar controller, and battery monitor. Looks like I can program them for current, time, and voltage charge controls which will meet the cell specs. I currently have 640W of PV on the roof, which is the max that fits sadly. I have plans for 100A direct charging from the alternator, which I have had good success with.

Here is the battery box design. Its a section view for obvious reasons, not actually cut down the side. Design is intended to drop through a hole in the floor to minimize interior space loss. Compression plates on either end with 1/4" threaded rod to connect them. Not sure how I will tie the batteries down, but thinking about nylon straps, but a bolt and hook design may also work. The plan is to order some laser cut steel sheet (16 gauge?) and weld it up.

The cells are EVE 280AH type from the Xuba seller. Should be getting those next month.

BMS is still in flux, but strongly considering a Orion Jr, and Gigivac or Blue Sea Latching relay for disconnect.

Our van is our home for years at a time when we travel various countries, so we are pretty serious about our comfort and power systems. This pack combined with a custom mini split will let us sleep in comfort when the heat index is triple digits F. A long thread on the van is over here.

Looking at making custom bus bars from 2/0 copper braid. I would be soldering solid copper pads for each terminal connection.

https://www.mcmaster.com/69925K43/

GEORGIA COPPER - Tinned Copper Braid

Tinned Copper Braid for Flexible Ground Connections

www.gacopper.com

The box will be insulated with 0.5 or 0.75" XPS foam. Looking at a 65W 12v heating pad for the bottom.

I have an existing outback inverter, solar controller, and battery monitor. Looks like I can program them for current, time, and voltage charge controls which will meet the cell specs. I currently have 640W of PV on the roof, which is the max that fits sadly. I have plans for 100A direct charging from the alternator, which I have had good success with.

Last edited:

IMG_20200718_101017545

IMG_20200718_101017545 IMG_20200718_101240667

IMG_20200718_101240667 IMG_20200718_113936051

IMG_20200718_113936051 IMG_20200718_132334698

IMG_20200718_132334698