Hello,

First of all, it is my first post here and I would like to thank you for this mine of information on the forum, it's great to have so much technical information in one place, bravo!

I'm going to assemble my first battery with LFP cells and I would like to have your opinion and advice to be sure to do things properly.

I have ordered from Jenny (Docan) 160Ah EVE cells and a 200A JBD BMS (with the heater port) which should arrive soon.

The battery will be used as an auxiliary battery in a small Campervan to replace an aging AGM battery. The van is used, all year long, in Europe, that's why I tried to thermally insulate the cells and added a heating pad.

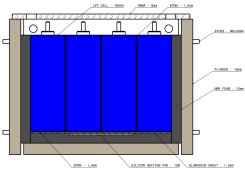

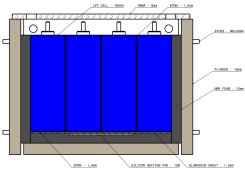

I share with you some illustrations of the assembly I plan to make:

I have some doubts about :

- compressing the cells : I have the impression that this is a subject of debate here, is it worth it for 160Ah cells ? in the idea I left a gap to eventually compress the foam a bit when tightening the case, but I have no idea of the effort that will be applied.

- heating pad : it's a 15W pad, with a possible outside temperature of -10°C, I have no idea if it will be enough to bring the cells above 0°C or 5°C for the recharge.

- heating pad : it's a 5$ pad on Aliexpress, do you have any feedback on the durability of this kind of pad ? risks in case of failure ?

- insulation and heat dissipation : I decided to insulate the cells for the cold but as a consequence it also limits the heat dissipation. The battery will be charged either by a solar panel with 20A maximum, or by a DCDC booster with 30A. I don't realize how much energy is dissipated per cell and if there is a risk of overheating the cells during the charge or discharge.

If you have any comments or feedback, I'm interested! Thanks

First of all, it is my first post here and I would like to thank you for this mine of information on the forum, it's great to have so much technical information in one place, bravo!

I'm going to assemble my first battery with LFP cells and I would like to have your opinion and advice to be sure to do things properly.

I have ordered from Jenny (Docan) 160Ah EVE cells and a 200A JBD BMS (with the heater port) which should arrive soon.

The battery will be used as an auxiliary battery in a small Campervan to replace an aging AGM battery. The van is used, all year long, in Europe, that's why I tried to thermally insulate the cells and added a heating pad.

I share with you some illustrations of the assembly I plan to make:

I have some doubts about :

- compressing the cells : I have the impression that this is a subject of debate here, is it worth it for 160Ah cells ? in the idea I left a gap to eventually compress the foam a bit when tightening the case, but I have no idea of the effort that will be applied.

- heating pad : it's a 15W pad, with a possible outside temperature of -10°C, I have no idea if it will be enough to bring the cells above 0°C or 5°C for the recharge.

- heating pad : it's a 5$ pad on Aliexpress, do you have any feedback on the durability of this kind of pad ? risks in case of failure ?

- insulation and heat dissipation : I decided to insulate the cells for the cold but as a consequence it also limits the heat dissipation. The battery will be charged either by a solar panel with 20A maximum, or by a DCDC booster with 30A. I don't realize how much energy is dissipated per cell and if there is a risk of overheating the cells during the charge or discharge.

If you have any comments or feedback, I'm interested! Thanks