timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,443

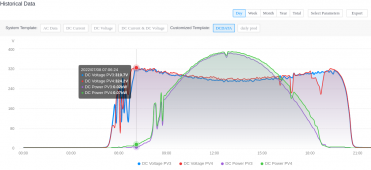

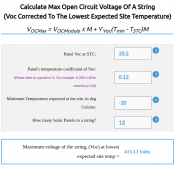

The SCC pauses periodically and checks the voc, throughout the day. Every time it adjusts the MPP.you're right, my math was off by a decimal! sorry for that, i fixed it, final figure is Delta T of 69.6 (which translates to roughly -44.6 degrees after redacting the 25 STC).......

Still,

1) Do you get to -45 where you live?

2) Even if you did get to -45, you still haven't tackled the part related to WHY would the SCC would see it as a OPEN-CIRCUIT? is it a separate charge controller without inverter? is there no constant load on inverter? is it not an all-in-one inverter with SCC, MPPT, inverter, AC-DC charger? they way i see it, you should almost never have Zero load, the inverter alone consumes anywhere between 50 to 70 Watts, a baseline load (fridge, router, mobile charger, etc...) would constitute at least 250 ~300W on top of the inverter consumption at idle.....

I assume that this is when it tripped on high bus voltage. Reducing to 10 panel strings fixed the issue.