MadMax03

New Member

- Joined

- Sep 21, 2019

- Messages

- 249

Doesn't work like that with an alternator in a car application. The ECU must sense battery state. My vehicles are Mercedes W221 S Class and W212 E Class. My competition stereo car with the 120ah LTO bank is a 5th gen Maxima.Any BMS that uses a relay or contactor.

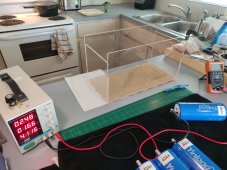

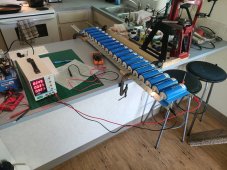

I thought about that, wasn't sure what the benefit would be? I series out to get my voltage then parallel out to get my capacity. Other than monitoring cells, which I'm not (I will check them manually, or throw an Arduino wifi monitor that I built on them), I am not aware of any benefits.Why did you wire the cells like that?

You've got three 12v packs in parallel.

I'd rewire that to put 3 cells in parallel. Then 4 of those in series.

DC Power Inc. At $750 each, they're not cheap, but I have had nothing but good things to say about them, and I own three.Also, 320 amp alternator! That's a hell of a thing

DC Power Inc. - High Output Alternators!

Whether you’re into racing, off-roading, RVing, or have a 10,000 watt stereo system in your daily driver, you’ve come to the right place. DC Power Engineering Inc. alternators are engineered from the ground up for those that demand the very best. Engineering is more than a word to us – it’s our...

www.dcpowerinc.com

www.dcpowerinc.com