Hi! Anyone used this BMS from LLT Power:

https://www.lithiumbatterypcb.com/product/7s-to-20s-200a-smart-bluetooth-bms/

Model No: JBD-AP20S002

Looks like a good bargain, what your views?

View attachment 18897

My 200A BMS' have arrived from China, I ordered from Shenzhen E-Fire Technology Development Co., Ltd on Alibaba.

The listing's photos were the same as above / ebay / etc.

This unit is massive, almost the size of a 1L carton of milk, probably the size of a CALB grey 3.2V cell.

4.65cm * 11.77cm * 23.7cm

The cables are 11mm diameter with shrink wrap protected M10 hole copper lugs. The cable itself says 4AWG 200 deg C.

The Aluminium extrusion and end caps have scratches and scuffs of about the same cosmetic appearance that a Bitcoin ASIC miner arrives from China.

There are no mounting holes, unlike the advertisement picture and no opening/flap on the top.

Lily provided me with some manuals and wiring instructions for 8s, which were all in Chinese. I asked for the BMS leads to be labelled, which was done.

My batteries are still en-route by sea, and the battery boxes are to be fabricated. This BMS is so big it might not even fit inside the metal boxes I've ordered from Shenzhen Xuba with 8s 280Ah.

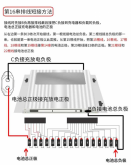

Here are the wiring documentation recieved.

My friend sent me this translation

When connecting the wires:

First, connect the “B負”(B-) to the “電池總負極”(total battery -),then the “排線”(cable series?).

Next, connect “C負”(C-) to the “充電器負極”(charger-).

Last, connect “電池總正極”(total battery +) to the “充電器正極”(charger+).

————————-

“排線”(cable series):

Starting from the right, connect wire to:

Wire-1: 電池總負極(total battery -)

Wire-2:第一串電池正極(battery series 1)

Wire-3: 第二串電池正極(battery series 2)

Wire-4: 第三串電池正極(battery series 3)

Wire-5: 第四串電池正極(battery series 4)

Wire-6: 第五串電池正極(battery series 5)

Wire-7 to Wire-19: 第六串電池正極(battery series 6)

Wire-20: 第七串電池正極(battery series 7)

Wire-21 &Wire-22: 電池總正極(total battery +)

And for this second image , the translation

The instruction is pretty much the same as the other one.

Connect every extra battery using wire-7 to wire-19.

Only difference on this table is that: J3 “未使用”(not used).

With the leads pre-labelled by Shenzhen E-Fire it looks pretty self explanatory.

There are 22 wires from BC0-BC21

BC0 (wire #1) goes to cell 1 negative

BC1-BC5 go to cells 1-5 positive

BC6-BC18 go to cell 6 positive

BC19 goes to cell 7 positive

BC20-21 go to cell 8 positive