BigGElmo

New Member

- Joined

- Feb 2, 2022

- Messages

- 16

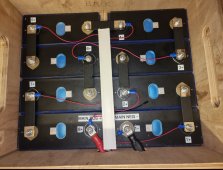

Hi, I've built a nice 24v 304ah EVE LiFePO4 battery with a JK BMS to power my Camper van, the 8 cells are in a plywood box and are under compression.

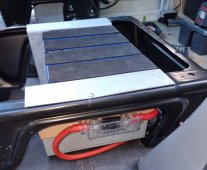

My problem is that the battery box is on the floor in the main living area and I'd really like to lose it to gain more floor space, my only option is to split the pack in to 2 seperate 4 cell packs and place one pack of 4 cells in each of the driver and passenger seat bases, but with the packs in the seat bases the BMS balance wires will now be to short.

So what are my options ?

A 4s BMS for each pack ?

Lengthen the BMS balance wires ?

Or what else can you suggest.

Cheers from the UK.

My problem is that the battery box is on the floor in the main living area and I'd really like to lose it to gain more floor space, my only option is to split the pack in to 2 seperate 4 cell packs and place one pack of 4 cells in each of the driver and passenger seat bases, but with the packs in the seat bases the BMS balance wires will now be to short.

So what are my options ?

A 4s BMS for each pack ?

Lengthen the BMS balance wires ?

Or what else can you suggest.

Cheers from the UK.