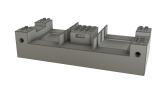

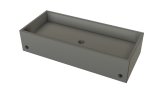

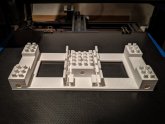

I'm planning to build a couple 12v batteries using the 280ah cells. Every since seeing the Fortune batteries on a couple of Wills videos I have been thinking about making my own pieces on my 3d printer. This is my current design. I'm thinking of using Lego like features to allow a top cover for each cell to snap on. I won't be using the series connection to join cells end to end but I notched it out if needed. That would require a busbar with an offset. The extra pieces near the middle should allow bms wires to be routed there. I still need to decide where to mount a bms. Maybe on the top piece? Thoughts/Feedback.

Attachments

Last edited: