superman22x

New Member

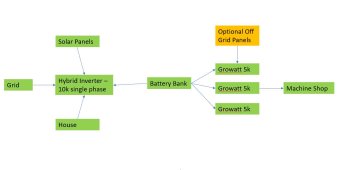

I am planning a solar install for a new build (couple years out at this point...) and I wasn't sure if someone had some feedback on 3 phase. I have a couple tools in my shop now that run 3 phase through VFDs. But in the future, I'd like to be able to easily add a few more, including a ~15hp CNC at some point. Rather than VFDs on everything, these get expensive when you talk about 3+hp motors, I was thinking I'd have a Rotary Phase Converter. Then I got to thinking, maybe there is a better way if I had a solar system with battery backup already planned. Growatt off grid have the option to pair 3 into a 15kw three phase system. I came up with the following diagram. Is this a good way to add a three phase shop off a solar system with a single phase grid-tie? Second advantage would be the ability to add cheaper "Off Grid Use only" panels from Santan to the 3 phase side of things.

I'm thinking the Hybrid inverter would need to maintain the batteries to a minimum state of charge from the grid so the 3 phase equipment has power on days when the solar system isn't putting out.

Sizing, I'm thinking around a 10-12kw array at this point. This will cover most of my household needs in the warmer time of year and require some grid backup in the cold months. Batteries in the 15-20kwh range.

Is there a better configuration that could do the same thing? Or should I stick with the original plan of getting a rotary phase converter (roughly similar price to three Growatt 5ks). I think only the Off Grid Growatts had the ability to do the three phase setup, so the Hybrid inverter is needed on the other side of the battery. I'd be ok with a basic grid-tie on the other side of the battery as well, I could have a circuit off one of the Off-grid inverters that powered critical functions during the 1 or 2 days a year power outage.

Thanks!

I'm thinking the Hybrid inverter would need to maintain the batteries to a minimum state of charge from the grid so the 3 phase equipment has power on days when the solar system isn't putting out.

Sizing, I'm thinking around a 10-12kw array at this point. This will cover most of my household needs in the warmer time of year and require some grid backup in the cold months. Batteries in the 15-20kwh range.

Is there a better configuration that could do the same thing? Or should I stick with the original plan of getting a rotary phase converter (roughly similar price to three Growatt 5ks). I think only the Off Grid Growatts had the ability to do the three phase setup, so the Hybrid inverter is needed on the other side of the battery. I'd be ok with a basic grid-tie on the other side of the battery as well, I could have a circuit off one of the Off-grid inverters that powered critical functions during the 1 or 2 days a year power outage.

Thanks!