rudydevolder

New Member

- Joined

- Jul 15, 2020

- Messages

- 18

I want some advice because I am not sure which configuration is best and how to improve:

Notice the micro-controller (I program myself) that is connected to:

=====================================================================

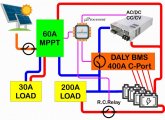

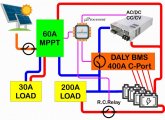

In this configuration I could use actually a cheaper and smaller BMS since the 200 Amp load is directly coupled to the batteries. The Remote Controlled relay is a protection I put to protect the batteries from overloading it with some voltage and current sensors. Actually it is already protected in the Kelly motor controller to protect batteries.

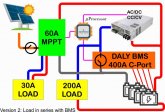

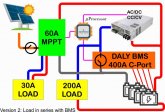

Version 2:

=======================================================================

Here I use the setup Will uses with the mains-charger and Daly BMS in series.

My hobby is electronics and programming: I use the ARDUINO to get diagnostics via the RS-485 bus on both my DALY BMS and MPPT controller. So, I also can reprogram the parameters in both controllers on the fly. I was thinking to charge primarily via SOLAR until a state of charge of 80 percent is reached and top it off using the mains to go through the DALY BMS with higher voltage settings and balancing the whole pack.

My questions:

Q1: Like I said configuration 1 will also work since I have my expensive 400 Amp controller already I think I'll go better for config 2 to make it safer. But like I said my Kelly motor controllers have already battery protection build in. So, I think the BMS will dissipate unnecessary power. Any suggestions?

Q2: I can charge through both MPPT and MAINS at the same time, no? Especially when my batteries getting low or the heavy motor-load comes in. Maybe I need to regulate the voltage of the mains-supply to a slightly lower voltage to give the Solar power priority?

Q3: Putting a DIODE in series to avoid power running into my mains-supply when it is remotely switched off; needed?

Q4: Concerning the operating modus of my DC power supply: CC or CV:

Q5: Do I need to change/protect more?

Any help is appreciated.

Notice the micro-controller (I program myself) that is connected to:

- The AC/DC mains connected power-supply: MeanWell CSP-3000/120 (Mains-AC to DC 30 AMPS): Can be remote controlled in either CV or CC modus. Also remotely controlled to power ON/OFF. And the max. output voltage is 120V DC can be lowered through either a potentio-meter or an external controlled voltage controlled by an ARDUINO. I plan on using an ARDUINO controller programmed myself. I plan to use this power-supply as some kind of backup or added power for my heavy load which is actually a 10Kw / 60 Volts BLDC-motor for my cable cart. But the cable cart is only working few times a day. The 30 Amp load is my house and so can be connected directly to the load output of my MPPT which is limited to 30 Amps.

- DALY BMS: the one I already have is a 400 Amps common port and can be remotely controlled through RS-485.

- MPPT solar controller model TYC-60A60V: so 60 Amps 60 volts; has also RS-485

- 200 Amp load: 10 Kw BLDC motors controlled by a Kelly BLDC controller which has CAN-bus and analog inputs/outputs.

=====================================================================

In this configuration I could use actually a cheaper and smaller BMS since the 200 Amp load is directly coupled to the batteries. The Remote Controlled relay is a protection I put to protect the batteries from overloading it with some voltage and current sensors. Actually it is already protected in the Kelly motor controller to protect batteries.

Version 2:

=======================================================================

Here I use the setup Will uses with the mains-charger and Daly BMS in series.

My hobby is electronics and programming: I use the ARDUINO to get diagnostics via the RS-485 bus on both my DALY BMS and MPPT controller. So, I also can reprogram the parameters in both controllers on the fly. I was thinking to charge primarily via SOLAR until a state of charge of 80 percent is reached and top it off using the mains to go through the DALY BMS with higher voltage settings and balancing the whole pack.

My questions:

Q1: Like I said configuration 1 will also work since I have my expensive 400 Amp controller already I think I'll go better for config 2 to make it safer. But like I said my Kelly motor controllers have already battery protection build in. So, I think the BMS will dissipate unnecessary power. Any suggestions?

Q2: I can charge through both MPPT and MAINS at the same time, no? Especially when my batteries getting low or the heavy motor-load comes in. Maybe I need to regulate the voltage of the mains-supply to a slightly lower voltage to give the Solar power priority?

Q3: Putting a DIODE in series to avoid power running into my mains-supply when it is remotely switched off; needed?

Q4: Concerning the operating modus of my DC power supply: CC or CV:

I'm afraid to work in CC modus since my power-supply can deliver 120 Volts it can destroy my BMS. I didn't test yet but I think in CC modus I can't put a max. voltage it's either CC or CV when I look into the data-sheet:

- I think I can just charge using the CV-modus and limit the current through my DALY BMS to avoid my power supply to go in overload-protection?

- Or do I need to put it in CC-modus and limit the current to 30 Amps? Than I'm afraid the Voltage can go to high when the battery is almost full; the DALY BMS will protect?

- I can also program everything to go from CC to CV automatically when the Voltage is above a certain level but that make it more complex.

Any help is appreciated.

Last edited: