I am working on a 300Ah battery for my sailboat. This is replacing 230Ah of FLA. I am using an Overkill solar BMS, Renogy 60 DCDC Charger, and Victron 100/30 MPPT. Primary charging will be via solar, and only running the engine after a couple days of clouds. Solar worked with the smaller FLA bank, so it should work even better with the larger LFE bank. My usage maxes at about 100Ah per day. I also have a 20A Renogy AC charger, but probably won't have that permanently connected, but will just carry it so I can use it if needed.

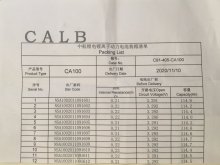

I purchased the cells from Electric Motorsports. They shipped from California in the factory crate from Calb, with the factory test data in the crate.

https://www.electricmotorsport.com/...lb-ca100-3-2v-100ah-lithium-battery-cell.html

I will be top balancing this weekend. Bus bars are 1/8" x 3/4", and I feel that might be a bit on the small side, there isn't much material left around the holes.

I purchased the cells from Electric Motorsports. They shipped from California in the factory crate from Calb, with the factory test data in the crate.

https://www.electricmotorsport.com/...lb-ca100-3-2v-100ah-lithium-battery-cell.html

I will be top balancing this weekend. Bus bars are 1/8" x 3/4", and I feel that might be a bit on the small side, there isn't much material left around the holes.