waiapasi2006

New Member

- Joined

- Mar 27, 2021

- Messages

- 51

Hello all.

I got these battery in from the long waiting list.....

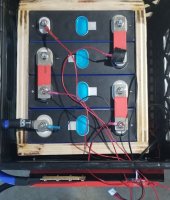

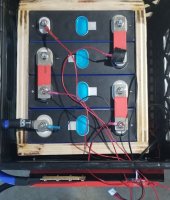

These are 230AH eve Cells. A total of 8.

I had top balanced the cells to 3.65 v and built a single 4S pack for testing their capacity.

This is what I have below. I did build a small box to help keep the cells intact.

Yes, did stick them in a milk crate for easy transportation.

My test at first.

used a heat gun.

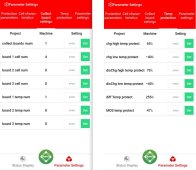

What threw me off was the 13A on the heat gun vs. what the Dally app was showing 130.7A.

The wat meter showed 1428 watt pulled from the inverter and the clamp meter 130.6A ( Almost the same from the dally mobile app)

I ran this test for about 10 minutes to see if the inverter will hold up.

My question,

Why is the Dally app showing 130.7A vs 13A?

But, I was surprised that everything was cold to the touch.

Edit: Thanks to Forum and everyone here I was able to take on this project!

I got these battery in from the long waiting list.....

These are 230AH eve Cells. A total of 8.

I had top balanced the cells to 3.65 v and built a single 4S pack for testing their capacity.

This is what I have below. I did build a small box to help keep the cells intact.

Yes, did stick them in a milk crate for easy transportation.

My test at first.

used a heat gun.

What threw me off was the 13A on the heat gun vs. what the Dally app was showing 130.7A.

The wat meter showed 1428 watt pulled from the inverter and the clamp meter 130.6A ( Almost the same from the dally mobile app)

I ran this test for about 10 minutes to see if the inverter will hold up.

My question,

Why is the Dally app showing 130.7A vs 13A?

But, I was surprised that everything was cold to the touch.

Edit: Thanks to Forum and everyone here I was able to take on this project!

Last edited: