bigbrovar

New Member

Hi guys, I am completely new to Lifepo4 cells having just set up my bank less than 2 weeks ago. I did alots of research and had to unlearn everything from using Lead Acid batteries for over 6 years.

I have Eve LF280K 16s

BMS is JBD 7S-20S 200A

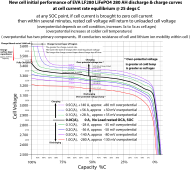

One area I am a bit unclear about is around absorption of this cells. A lot of the literature I have read says Lifepo4 does not require long absorption, in fact it is stated that once the set pack voltage is reached and tail current drops to C0.05 charging should stop.

I use a Victron Smart MPPT charge controller. The charge controller is no way of determining the battery charge current (The actual current going into charging the battery as against powering the house) so there is no way to base charging on tail current.

Victron has a LifeP04 profile which it sets to 2 hours of absorption. My concern is most of the literature seem to suggest 2 hours is too long for absorption and should in fact be not more than 30 minutes. I am new at all this and I am a bit confused. I would very much not like to damage any of the cell in the pack so I come here to seek counsel on what the proper cause of action to take is.

My current charge profile

Absorption set to 56.8v

The goal is to have each cell charged up to 3.55v

Absorption time is set to 2 hours before switching to float which is set to 3.35v per cell or 53.6v for the bank.

I live completely off the grid and have a 5kw solar array for charging the system. Charge rate is usually below C.3 but has the potential to be as high as C.4.

I have Eve LF280K 16s

BMS is JBD 7S-20S 200A

One area I am a bit unclear about is around absorption of this cells. A lot of the literature I have read says Lifepo4 does not require long absorption, in fact it is stated that once the set pack voltage is reached and tail current drops to C0.05 charging should stop.

I use a Victron Smart MPPT charge controller. The charge controller is no way of determining the battery charge current (The actual current going into charging the battery as against powering the house) so there is no way to base charging on tail current.

Victron has a LifeP04 profile which it sets to 2 hours of absorption. My concern is most of the literature seem to suggest 2 hours is too long for absorption and should in fact be not more than 30 minutes. I am new at all this and I am a bit confused. I would very much not like to damage any of the cell in the pack so I come here to seek counsel on what the proper cause of action to take is.

My current charge profile

Absorption set to 56.8v

The goal is to have each cell charged up to 3.55v

Absorption time is set to 2 hours before switching to float which is set to 3.35v per cell or 53.6v for the bank.

I live completely off the grid and have a 5kw solar array for charging the system. Charge rate is usually below C.3 but has the potential to be as high as C.4.