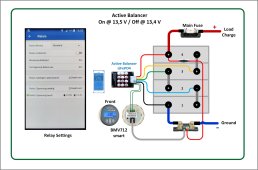

Appreciate and value these information!Good catch. I learned in the meantime, that 3.37 V is the "magic" number for the LFP cell to turn on the active Balancer. Reason: Even for the lowest possible charging current, 3.37 V indicates a full cell with SOC = 100%. I played around with low and high charging currents (I = 0.5 C) and recorded cell voltages during full charge / discharge cycles. I ended up with 3.37 V balancer On, and 3.34 V balancer Off being a good match.

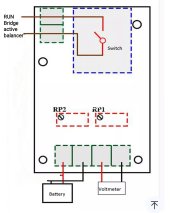

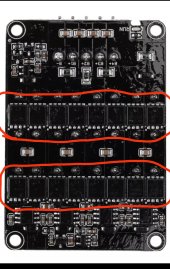

My KISS System produces a maximum balancing current of 4 A. The current is proportional to the voltage difference of the cells (same is true for the Heltec 5 A balancer). Due to the fact, that the balancing current becomes zero, once all cells are balanced, one can be sure, that the balancer reads actual cell voltages not being affected by a voltage drop at the balancer wires!

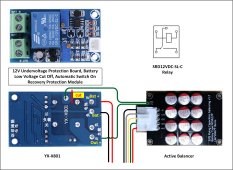

As promised I will get you some circuit diagrams next week.

Regards Hans

Vielen herzlichen Dank!