thanhrodke

New Member

- Joined

- Sep 8, 2022

- Messages

- 131

Evening everyone,

I dug through search results, and saw lots of stuff related to adding one or more individual batteries, but nothing stood out about expanding an entire rack of batteries, so here's my first post asking a detailed question.

I've got another six EG4 LifePower4 48V lithium batteries (https://signaturesolar.com/eg4-lifepower4-lithium-battery-48v-100ah) and EG4 rack arriving this week. I'll be connecting them to an existing system that has six of the same battery, with the 12 batteries powering two EG4 6000EX-48HV 120/240V inverters (https://signaturesolar.com/eg4-6k-off-grid-inverter-6000ex-48hv). This is a 100% off grid system, with no option for grid input, though there will be generator power available (likely a 15kW propane Generac).

Each inverter currently has it's own 60V 200A Nadar breaker acting as the positive disconnect, with the positive cable from each of those breakers to top of the battery rack's left bus bar. The ground bar on the right is flipped and both inverters ground cable is connected to the bottom of the right inverted bus bar. Both cables are factory terminated 84" 1 gauge cables from signature solar.

When connecting the second battery bank, any issues with connecting it directly to these same points on the existing battery rack's bus bars? I'd flip the ground bus bar as on the first one, and using the same factory terminated 84" 1 gauge wire. Since there's no changes to the inverters, we don't have a current stacking issue like when wiring batteries in parallel. Total current running through the system will remain the same, as there are no changes to the inverters.

That said, there may be better alternatives, so please correct me if my logic above is not correct:

Ultimately, this system will just have the two inverters and two battery banks. However, I will be building another system in a few months that will have four inverters and four racks of batteries with about 30kW of panels, so that's open for discussion here as well.

I dug through search results, and saw lots of stuff related to adding one or more individual batteries, but nothing stood out about expanding an entire rack of batteries, so here's my first post asking a detailed question.

I've got another six EG4 LifePower4 48V lithium batteries (https://signaturesolar.com/eg4-lifepower4-lithium-battery-48v-100ah) and EG4 rack arriving this week. I'll be connecting them to an existing system that has six of the same battery, with the 12 batteries powering two EG4 6000EX-48HV 120/240V inverters (https://signaturesolar.com/eg4-6k-off-grid-inverter-6000ex-48hv). This is a 100% off grid system, with no option for grid input, though there will be generator power available (likely a 15kW propane Generac).

Each inverter currently has it's own 60V 200A Nadar breaker acting as the positive disconnect, with the positive cable from each of those breakers to top of the battery rack's left bus bar. The ground bar on the right is flipped and both inverters ground cable is connected to the bottom of the right inverted bus bar. Both cables are factory terminated 84" 1 gauge cables from signature solar.

When connecting the second battery bank, any issues with connecting it directly to these same points on the existing battery rack's bus bars? I'd flip the ground bus bar as on the first one, and using the same factory terminated 84" 1 gauge wire. Since there's no changes to the inverters, we don't have a current stacking issue like when wiring batteries in parallel. Total current running through the system will remain the same, as there are no changes to the inverters.

That said, there may be better alternatives, so please correct me if my logic above is not correct:

- Feed the breakers in parallel:

Convert the lugs on the Nadar breakers to double mechanical lugs, and tie both battery racks to input side of the existing breakers. The inverters will still have a single 1 gauge cable from the output of the breaker to the input of the inverter. With a single breaker, I understand that I can't take one battery pack offline for maintenance. - Individual breakers for all:

Connect the new battery bank to it's own breakers, then up to the inverters (though not sure there's room to convert the inverter to double mechanical lugs). If this is recommended, what's the recommended method for connecting to the inverters? Is it to use bus bars after the breaker? This doesn't seem right, as it's not an inverter disconnect at this point, it's a battery disconnect. You'd have to flip two breaker (or maybe even four) to shut down one or more inverters, depending upon how parallel you went with the bus bars. - Single breakers with bus bar before the breakers:

Move to a bus bar setup (introduces at least some resistance and heat) where each battery connects to a bus bar, then a single output from the bus bar feeds a single breaker for each inverter input. In this case, how do you disconnect a given battery rack? - Inline breakers between battery racks:

Wired as originally proposed, but add breakers inline between the second battery rack and the first. This would allow the second battery pack to be taken offline and serviced, but not the first (by itself). - Breakers everywhere:

Use breakers as close to each battery rack as is feasible, then tie all of those battery banks to a common bus bar. - Wire battery racks 1:1 with inverters:

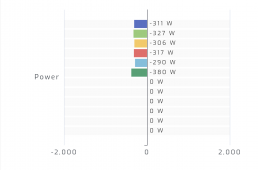

I've watched the inverters closely the last few weeks, and think that they reasonably share the AC output load, so that even if the system were two battery/inverter systems running in parallel, both batteries will be charged and discharged pretty close to each other. Even if they different by a few percent, that's not the ideal scenario - Wire battery racks 1:1 with inverters:

Same at #6, but have a set of 1 gauge parallel cables between battery banks to keep them a little better balanced.

Ultimately, this system will just have the two inverters and two battery banks. However, I will be building another system in a few months that will have four inverters and four racks of batteries with about 30kW of panels, so that's open for discussion here as well.