I am still fairly new on the forum, tried to answer a few questions as I asked some, and have been talking about my plans and purchases. I figure this is the right place to talk about what I am doing and where it is going.

My existing system is a very typical Enphase setup. I have 2 arrays of 8 panels each. The panels are Sil Fab 300M 60 cell units with an iQ7 inverter on each one. All 16 inverters are combined in the attic and go to an Envoy iQ3 on the wall of my garage near the power meter. I am at the limit of a single run with the 16 inverters. I have space to add more, but my existing main breaker panel is only a 100 amp unit, which limits me to a 20 amp feed in from the solar power system.

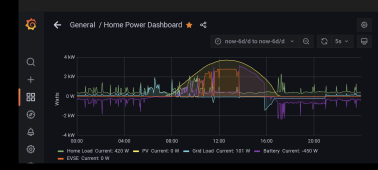

The system has now been running for just over a year and has been performing great. My south facing roof is at 210 degrees, so I stretch the usable sun a little into the evening, and the tilt of the roof is about 20 degrees which give very good exposure with the peak power in spring and fall. The 300 watt panels were actually able to clip the inverters for over an hour in May, pushing over 3,840 watts into my breaker panel. My production averages over 25 KwH a day and topped out at almost 32 KwH with all 16 panels making close to 2 KwH each. That is well more than I expected to get out of 300 watt panels. That works out to 6.7 sun hours. In summer (now) the panels are running a bit hot and the sun is higher than my 20 degree tilt, so I am not quite topping out the panels and inverters like it was in spring. Today, each panel was close to 1.7 KwH of production, for 26.4 KwH total. That is still 5.5 sun hours. Peak power was down to 3,460 watts.

During sunny cool days, I am pushing over 10 KwH back on the grid only to buy most of it back at a much higher rate. Even in these hot summer days, I still push over 5KwH out and have to buy much more to run the A/C in the evening. I knew I wanted to do "Time of Use" shifting with storage at some point. I was waiting on the Enphase Ensamble system, and looking into their batteries, but I just could not accept the cost for the rated performance. And the fact I would have to pay the installer almost as much as I did for the original solar gear install. So a few months ago, I really started looking into other storage options. The Tesla Powerwall 2 was looking like a fair deal, but it came with more than a few strings, and few installers would work with my existing system, and my original installer, does not work with Tesla. And trying to get a Powerwall 2 for a DIY install is not going to happen here in So Cal.

I looked into a few other ideas, but for safety reasons, I narrowed it down pretty quickly to Outback, SMA, and Schneider. I looked at Growatt and Sol Ark also, but they didn't have all the features I wanted. The Outback Skybox almost won, and has had some great reviews, but looking over the manuals, I was not totally convinced. The "one box does it all" system sounds great, but in the end, I liked the flexibility of the Schneider a bit better. So today, I placed my order for a Schneider XW-Pro 6848 inverter with the Conext Gateway box. It went on sale for a good price and a free shipping offer, so I clicked go. I should have it here by this weekend.

I have already talked about my battery on a few other posts, but I will summarize it here. Our friends at Battery Hookup had a great deal a few weeks back, so I picked up 3 LG Chem battery modules from a Chevy Bolt. I got 2 of the 10S 3P and one of the 8S 3P. I only had to cut one buss bar to split the 8S into two 4S groups. Then wired each 10S with a 4S and then paralleled the two 14S groups. The end result is 14S 6P of LG 3.7 volt 60 amp hour NMC pouch cells. 51.8 volts at 360 amp hours total or 18,684 watt hours. I figure about 17 KwH useable, but I do not plan to run them below 30% or charge them above 90% unless I am in a power fail condition. That gives me about 11 KwH to use every day for "time of Use" shifting which should just about eliminate any extra solar going to the grid and doing all self consumption. I am using the JK BMS with active cell balancing and the Bluetooth App. I have the 200 amp version that will do up to 24 cells and 2 amps of balance current. These nearly new LG cells are testing very well balanced so far, but without the inverter charger, I have only been able to push and pull 10 amps into the pack. Once the inverter is up and running, I will be able to give the pack a real test.

For the initial setup, I will just do time based control and have it charge at 1 KW for 10 hours while the solar is producing, and then push back 2 KW into my home during the peak rate 5 hour window. I may add a "WattNode" later to have it do true "Zero Sell" and the Schneider "Batt Mon" to give it more acurate battery status for "State of Charge" control of the store and sell as well as more accurate control if I have to run off grid during an extended power failure. Without the Batt Mon, it only uses battery pack voltage. These Li NMC cells have such a flat discharge curve, it can barely tell between 75% and 50% state of charge without measuring the current going in and out of them. My BMS reports a very accurate SoC, but for now, the Schneider inverter can't get the data from the JK BMS. That may happen in the future as the BMS does have both a CAN port and RS485 port for wired communication. I may be able to program an Arduino to read the BMS and report the data as if it is a Schneider Batt Mon.

Since this is the "Show and Tell" area, I will post a few pictures.

View attachment 19680View attachment 19681

I will add a few more soon. I do have a few pics of the array etc. And even a few of the panels going up that I took with my drone.