krby

Solar Enthusiast

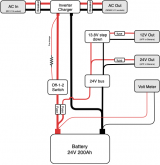

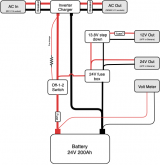

UPDATE: I'm posting updated parts and diagrams in the thread as I go, leaving the existing drawings in place so the thread makes sense.

In another thread, someone suggested I could post here for advice.

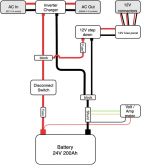

I'm building a portable electric generator similar to Goal Zero or Kodiak but without the solar charging capabilities. It's basically a battery bank, a charger, and an inverter in a portable box, probably one with wheels on it. We'll use it at home during blackouts, while camping, and for charging batteries on R/C flying. I'll start off with the my first attempt at a wiring diagram:

I'll charge it from house AC and leave it charged most of the time. When "in use", I'll move it close to the load, and plug the load into an AC socket the box. I know I'm not taking great care of the batteries by leaving them charged most of the time, I expect maybe a few hundred cycles over maybe 5 years. I'll definitely store the box somewhere Part of motivation for building this is the project itself, so replacing batteries in few years may happen anyway as part of upgrading.

I've spent some time sizing the loads and have settled on ~4kWh and 2000W of power. Here's how I got there:

1) The worst case power draw will be ~1300W for a hair dryer or ~1000W charing R/C batteries.

2) The fridge plus other things we might want powered during a blackout take no more 1.5kWh a day, I'd like at least two days plus some headroom.

Here are the component I've spec'd out so far. I'm thinking I will purchase the large expensive bits (battery, charger, inverter, wiring, big fuse) get an idea of placement and size and then start looking at boxes before I buy any of the exterior parts.

24V 200Ah LFE battery

I'm focused on LFE because I want this to be lighter and smaller than I can get with SLA. Right now a 24V 200Ah from Specialized Power/Pacific Sun Systems is the front runner.

2000W Pure Sine Inverter

I haven't made a choice here, open to ideas.

24V LFE battery charger

Something like 25-50A feels like it would be good. 50A is a 0.25C charge rate on the battery bank. I'd consider an inverter/charger, or one of the all-in-one units Will has talked about and just not use the solar input. I don't need the automatic transfer feature, but saving money and space would be nice.

150A or 200A Fuse

The 24V/2000W inverters I've looked range from about 120-133A of max DC input, so rounding up to 150 or 200A. 150 might be cutting it close. In the attached drawing, I have only one fuse, do I need one each for the charger and the inverter? Or will those each have their own?

Wiring

somewhere between 2 and 2/0. Using this calculator

https://www.powerstream.com/Wire_Size.htm, and punching in 6ft, 150A, 24VDC. 2AWG gives a 1.2% drop, 2/0 gives 0.6% drop. I expect the actual distance to be shorter. Have I done this right? I'm fine buying slightly bigger wire, but because this is all going in a box I will need some tight bends.

Battery disconnect / Main switch

I think I need like some sort of disconnect that I can switch manually. Something switch that disconnects the battery from everything. Right now I'm looking at the regular Blue Sea switches that boat and RV folks use. But maybe something like the Sterling ProLatch or maybe just a relay with a switch mounted outside the box?

12V stepdown

12V is useful for a variety of things, I'll wire this up to various DC connectors like banana posts, PowerPole, maybe a "cigarette lighter" socket.

Fuse(s) for 12V outputs

For the 12V output, the wiring and connector ratings will be much lower than the main 200A fuse. Do I need a fuse per connector or can I use a single fuse between the output side of the 12V step-down? I can imagine using 10A on some PowerPoles.

AC Input

IEC socket for charger input, or just a regular cord.

AC Output

1 or 2 NEMA 15A AC sockets for the inverter output.

Switch(s) to control inverter and/or charger?

Not sure I need to control these separately on the outside. For ease of use, just one master switch might do it. Since this will be sitting for months at a time, I definitely don't want the inverter on all the time. Maybe this could just be the battery disconnect?

Volt / Amp power meter

I think I could do just volts, but I like the idea of a panel mounted display for amps. Will suggests a baylight one on Amazon, but I'm going to need 150-200A, right? I'm assuming I don't need to monitor the charging side, just a shunt on the output side, right?

I'm hoping the folks here can look everything over, point out what I'm missing or give whatever other advice they have. Thanks!

In another thread, someone suggested I could post here for advice.

I'm building a portable electric generator similar to Goal Zero or Kodiak but without the solar charging capabilities. It's basically a battery bank, a charger, and an inverter in a portable box, probably one with wheels on it. We'll use it at home during blackouts, while camping, and for charging batteries on R/C flying. I'll start off with the my first attempt at a wiring diagram:

I'll charge it from house AC and leave it charged most of the time. When "in use", I'll move it close to the load, and plug the load into an AC socket the box. I know I'm not taking great care of the batteries by leaving them charged most of the time, I expect maybe a few hundred cycles over maybe 5 years. I'll definitely store the box somewhere Part of motivation for building this is the project itself, so replacing batteries in few years may happen anyway as part of upgrading.

I've spent some time sizing the loads and have settled on ~4kWh and 2000W of power. Here's how I got there:

1) The worst case power draw will be ~1300W for a hair dryer or ~1000W charing R/C batteries.

2) The fridge plus other things we might want powered during a blackout take no more 1.5kWh a day, I'd like at least two days plus some headroom.

Here are the component I've spec'd out so far. I'm thinking I will purchase the large expensive bits (battery, charger, inverter, wiring, big fuse) get an idea of placement and size and then start looking at boxes before I buy any of the exterior parts.

24V 200Ah LFE battery

I'm focused on LFE because I want this to be lighter and smaller than I can get with SLA. Right now a 24V 200Ah from Specialized Power/Pacific Sun Systems is the front runner.

2000W Pure Sine Inverter

I haven't made a choice here, open to ideas.

24V LFE battery charger

Something like 25-50A feels like it would be good. 50A is a 0.25C charge rate on the battery bank. I'd consider an inverter/charger, or one of the all-in-one units Will has talked about and just not use the solar input. I don't need the automatic transfer feature, but saving money and space would be nice.

150A or 200A Fuse

The 24V/2000W inverters I've looked range from about 120-133A of max DC input, so rounding up to 150 or 200A. 150 might be cutting it close. In the attached drawing, I have only one fuse, do I need one each for the charger and the inverter? Or will those each have their own?

Wiring

somewhere between 2 and 2/0. Using this calculator

https://www.powerstream.com/Wire_Size.htm, and punching in 6ft, 150A, 24VDC. 2AWG gives a 1.2% drop, 2/0 gives 0.6% drop. I expect the actual distance to be shorter. Have I done this right? I'm fine buying slightly bigger wire, but because this is all going in a box I will need some tight bends.

Battery disconnect / Main switch

I think I need like some sort of disconnect that I can switch manually. Something switch that disconnects the battery from everything. Right now I'm looking at the regular Blue Sea switches that boat and RV folks use. But maybe something like the Sterling ProLatch or maybe just a relay with a switch mounted outside the box?

12V stepdown

12V is useful for a variety of things, I'll wire this up to various DC connectors like banana posts, PowerPole, maybe a "cigarette lighter" socket.

Fuse(s) for 12V outputs

For the 12V output, the wiring and connector ratings will be much lower than the main 200A fuse. Do I need a fuse per connector or can I use a single fuse between the output side of the 12V step-down? I can imagine using 10A on some PowerPoles.

AC Input

IEC socket for charger input, or just a regular cord.

AC Output

1 or 2 NEMA 15A AC sockets for the inverter output.

Switch(s) to control inverter and/or charger?

Not sure I need to control these separately on the outside. For ease of use, just one master switch might do it. Since this will be sitting for months at a time, I definitely don't want the inverter on all the time. Maybe this could just be the battery disconnect?

Volt / Amp power meter

I think I could do just volts, but I like the idea of a panel mounted display for amps. Will suggests a baylight one on Amazon, but I'm going to need 150-200A, right? I'm assuming I don't need to monitor the charging side, just a shunt on the output side, right?

I'm hoping the folks here can look everything over, point out what I'm missing or give whatever other advice they have. Thanks!

Last edited: