brooke_heaton

New Member

- Joined

- Sep 28, 2020

- Messages

- 31

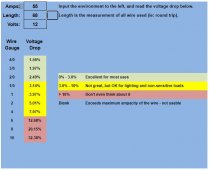

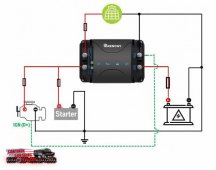

Hi all, I have a 15 ft vehicle towing a 15 ft trailer - likely 34 ft total with the tongue but I'm calculating 40 ft since it has to run around a few things. The batteries are in the rear of the popup. I have the Renogy DCC50S 12V 50A DC Board Battery Charger with MPPT which can charge while towing and I'm wanting to add a wire run from my starter battery to two Valence U27s in the rear of the camper. Since the wire needs to run 50 Amps over that distance, I've calculated a voltage drop of 8.88 %, 50 amps, and a final voltage of 12.76 at the charger if using 4 AWG which seems fine. The drop is 14% if using 6 AWG, which would be an easier fit.

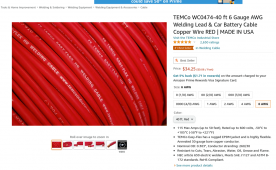

I'm looking at using TEMCo 6 AWG welding wire which is rated for 115 Max Amps (up to 50 feet), 600 volts, -50°C to +105°C (-58°F to +221°F). I don't quite understand this rating. The 4 AWG is rated at 150 Max Amps (up to 50 feet), 600 volts, -50°C to +105°C (-58°F to +221°F). The information mentions nothing about voltage, so I'm confused about how it's simply rated for Amps. I'm basically balancing voltage loss versus getting this wire fed through the car's firewall, through the interior, out the back in through the camper. Cost isn't so much the issue as ease of installation.

Anyway is this wire something that is MORE performative than regular wire?. Would I be safe with 6 AWG? Or do I need to go with 4 AWG here?

I'm looking at using TEMCo 6 AWG welding wire which is rated for 115 Max Amps (up to 50 feet), 600 volts, -50°C to +105°C (-58°F to +221°F). I don't quite understand this rating. The 4 AWG is rated at 150 Max Amps (up to 50 feet), 600 volts, -50°C to +105°C (-58°F to +221°F). The information mentions nothing about voltage, so I'm confused about how it's simply rated for Amps. I'm basically balancing voltage loss versus getting this wire fed through the car's firewall, through the interior, out the back in through the camper. Cost isn't so much the issue as ease of installation.

Anyway is this wire something that is MORE performative than regular wire?. Would I be safe with 6 AWG? Or do I need to go with 4 AWG here?