off.the.grid

New Member

- Joined

- Dec 26, 2021

- Messages

- 124

Ive just purchased an off the grid property with an old solar system that is pretty much at the end of its life.

There is alot to discuss, but I think its probably best to just provide the system specs and my observations on how its currently running.

I can provide photos if necessary.

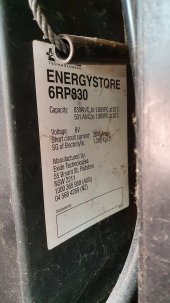

Battery bank, 4x 6V Exide 6RP830 energy store batteries (830Ah each) configured as 24V theoretically is about 20KW.

Also a bunch of forklift batteries of unknown capacity have been added at some point in parallel to the existing bank, there are 12x 2V cells providing 24V although one cell is completley dead and the electrolyte has gone grey. This must cause some issues.

Now I have absolutely no way to tell what charge these batteries actually hold, other than going by the hydrometer that points to fair, somewhere in the middle. The forklift batteries are actually reading better.

The whole voltage readout on the bank reads about 25V or so with the charger and load disconnected. It was dropping off to around 23V if we were using alot of power during the day such as a pool pump and then the inverter would cut off and the alram sound.

The seller of the property told us if we wanted to run a toaster to turn on the generator. But with the battery capacity, we should not have had any issues. I have not as of yet performed any such load tests to see how it holds up, but we did have the system shut down once when running the pool pump and other water pumps one day, probably hit 700W or more at its peak i assume if our refrigerators were running.

Now on to the panels, at this time, I had not discovered there was a fault on the charging system and that only 2 panels were charging the whole system!

There is only 5 panels on this installation which would not be much to charge batteries of this capacity in a timely fashion.

There are 2x mitsubishi pv-AD180mf5 panels in parallel feeding a morningstar SS-MPPT-15L controller. Specs say these are rated at 180W each.

I was getting about 15-16A (according to the panel on the wall) output alone from this on a sunny day. Voltage output was reading about 49-50V

Now on to the other set of panels, there are 3 schott ASE-165-GT-FT/MC panels in parallel, this was not even working when I arrived.

After inspecting the switchboard, I found that a wire had corroded away and melted that lead to the solar controller, after repairing, its all working fine.

It looks like a bird or rodent had pooped on the wiring and caused some damage.

The controller is a morningstar TS-45 and when this was running, I got about 6A according to a digital readout on the panel.

Now the interesting bit is that the output from the other charge controller drops a bit when this one is running (all the charge controllers are in parallel)

So I dont really get that much overall gains from all the panels combined.

Is this possible that this is because it is detecting that the battery bank is almost full perhaps? I suspect its the case since the meter reads zero when the generator is charging.

What is the maximum charge current such a configuration of flooded wet cells can handle?

Now the inverter is a beefy unit and looks like its rated at 4400KW from what i can take. It also appears late model and recently installed.

This charges the battery bank when the generator is running.

It is a Steca HP-Compact 4400-24

Charge voltages with generator running is around 28.4V-28.9V

Voltage with panels charging is about 27.5V

Im not sure if these voltages are typical for flooded wet cell batteries or not.

Anyway, I have bought some golf cart batteries that are a modest 220Ah each, I have got 8 of them, so with 4 in series, then 2 strings in parallel should give me 440Ah which is almost 10KWh capacity which should be more than enough for my setup to tie me over for a few more years when I will be ready to upgrade to something far more substantial.

I am also considering adding more panels, not too sure how many more I need, but realistically im probably only getting 500-600W at best on a sunny day.

Ive been taking note of panel voltages to try and work out what im really getting.

They are obviously old panels with less efficiency than modern ones, but I dont see any harm in using them in addition to some new ones to bump up capacity.

I was looking at some Suntech STP 410W-24 panels, probably another pair would be enough?

Open to any other suggestions.

TIA

There is alot to discuss, but I think its probably best to just provide the system specs and my observations on how its currently running.

I can provide photos if necessary.

Battery bank, 4x 6V Exide 6RP830 energy store batteries (830Ah each) configured as 24V theoretically is about 20KW.

Also a bunch of forklift batteries of unknown capacity have been added at some point in parallel to the existing bank, there are 12x 2V cells providing 24V although one cell is completley dead and the electrolyte has gone grey. This must cause some issues.

Now I have absolutely no way to tell what charge these batteries actually hold, other than going by the hydrometer that points to fair, somewhere in the middle. The forklift batteries are actually reading better.

The whole voltage readout on the bank reads about 25V or so with the charger and load disconnected. It was dropping off to around 23V if we were using alot of power during the day such as a pool pump and then the inverter would cut off and the alram sound.

The seller of the property told us if we wanted to run a toaster to turn on the generator. But with the battery capacity, we should not have had any issues. I have not as of yet performed any such load tests to see how it holds up, but we did have the system shut down once when running the pool pump and other water pumps one day, probably hit 700W or more at its peak i assume if our refrigerators were running.

Now on to the panels, at this time, I had not discovered there was a fault on the charging system and that only 2 panels were charging the whole system!

There is only 5 panels on this installation which would not be much to charge batteries of this capacity in a timely fashion.

There are 2x mitsubishi pv-AD180mf5 panels in parallel feeding a morningstar SS-MPPT-15L controller. Specs say these are rated at 180W each.

I was getting about 15-16A (according to the panel on the wall) output alone from this on a sunny day. Voltage output was reading about 49-50V

Now on to the other set of panels, there are 3 schott ASE-165-GT-FT/MC panels in parallel, this was not even working when I arrived.

After inspecting the switchboard, I found that a wire had corroded away and melted that lead to the solar controller, after repairing, its all working fine.

It looks like a bird or rodent had pooped on the wiring and caused some damage.

The controller is a morningstar TS-45 and when this was running, I got about 6A according to a digital readout on the panel.

Now the interesting bit is that the output from the other charge controller drops a bit when this one is running (all the charge controllers are in parallel)

So I dont really get that much overall gains from all the panels combined.

Is this possible that this is because it is detecting that the battery bank is almost full perhaps? I suspect its the case since the meter reads zero when the generator is charging.

What is the maximum charge current such a configuration of flooded wet cells can handle?

Now the inverter is a beefy unit and looks like its rated at 4400KW from what i can take. It also appears late model and recently installed.

This charges the battery bank when the generator is running.

It is a Steca HP-Compact 4400-24

Charge voltages with generator running is around 28.4V-28.9V

Voltage with panels charging is about 27.5V

Im not sure if these voltages are typical for flooded wet cell batteries or not.

Anyway, I have bought some golf cart batteries that are a modest 220Ah each, I have got 8 of them, so with 4 in series, then 2 strings in parallel should give me 440Ah which is almost 10KWh capacity which should be more than enough for my setup to tie me over for a few more years when I will be ready to upgrade to something far more substantial.

I am also considering adding more panels, not too sure how many more I need, but realistically im probably only getting 500-600W at best on a sunny day.

Ive been taking note of panel voltages to try and work out what im really getting.

They are obviously old panels with less efficiency than modern ones, but I dont see any harm in using them in addition to some new ones to bump up capacity.

I was looking at some Suntech STP 410W-24 panels, probably another pair would be enough?

Open to any other suggestions.

TIA