PeteW

New Member

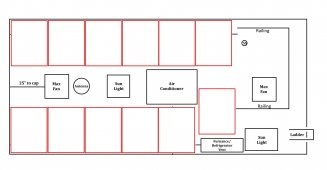

I own an 29' Airstream travel trailer. I'm adding 8, 100W PV panels to the roof. I'm still waiting (it's been a year now) on a 15K BTU Heat Pump for the roof, as indicated by the blue tape in the second picture. This is a rebuild project, so the shell interior is still unfinished. That means I still have really good access to everything. I'm looking for advice and or acknowledgement that I'm on the right track, no pun intended. From the pictures I'm posting you'll be able to see the brackets I'm still considering, but because of a plumbing vent it looks like I will also need to use some solid 12 gauge Aluminum 1-5/8" x 1-5/8" Strut Channel or similar and Channel Nuts of some kind preferably Stainless. Plus, I think using the solid aluminum struts will allow me to use VHB tape and Dicor to fasten them to the roof. Even if I do use some mechanical fasteners to hold the strut's on, I'll be able to do the job with far fewer. In case it's not clear the struts will run length wise and will be mainly for the four center panels. I'm also not sure how much clearance I need to allow for the plumbing vent. I do know that I don't want that odor backing up into the trailer.

I'm just spitballing at this point, but I figure I'll get some experienced advice here.

I'm just spitballing at this point, but I figure I'll get some experienced advice here.