Does anyone have experience with ETC cells? Good? Bad? depends on who you get them from and what questions you ask?

This is the only thread mentioning them on the forum, though the buyer didn't mean to buy them in the end he was satisfied (and confirmed through a PM that they are working after ~100 cycles).

I got a quote from Xuba for 4 x 280Ah ETC cells that are almost $100 cheaper (for set of 4) than their 280Ah EVE cells.

ETC: "Grade A with QR code"

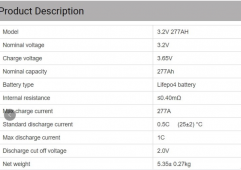

They send a screenshot of a portion of a datasheet. Things I noticed in that are:

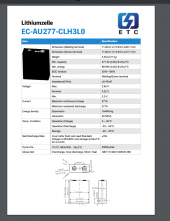

I found this data sheet online. It generally matches what they sent, except for discharge cutoff voltage. The photos look like at a minimum, a different wrap and cover on the cells...

Thanks for any insight you can give!

This is the only thread mentioning them on the forum, though the buyer didn't mean to buy them in the end he was satisfied (and confirmed through a PM that they are working after ~100 cycles).

I got a quote from Xuba for 4 x 280Ah ETC cells that are almost $100 cheaper (for set of 4) than their 280Ah EVE cells.

ETC: "Grade A with QR code"

They send a screenshot of a portion of a datasheet. Things I noticed in that are:

- 277ah capacity - OK I can live with that instead of 280. Really anything close but reliable is fine with me

- < 0.4mOhm - EVE (and maybe others?) state < 0.25 or 0.3mOhm

- discharge cutoff of 2V - is this a red flag? i thought 2.5 was the absolute lowest LiFePo4 should go

- weight of 5.3 kg looks right for the capacity

I found this data sheet online. It generally matches what they sent, except for discharge cutoff voltage. The photos look like at a minimum, a different wrap and cover on the cells...

Thanks for any insight you can give!