Directshort

New Member

- Joined

- Jul 14, 2020

- Messages

- 50

On my van the roof metal seems pretty thin so for a 200 watt panel do you think reinforcing backing plates are needed under the solar panel mounting brackets?

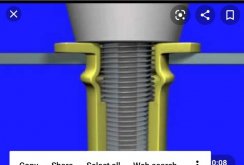

I will be using 3M tape under the mounts but being a newb considering adding a bolt through the 2 front mounts for added safety but it would seem at a minimum some thin plywood or other material glued inside would help the roof deforming. I dented it just with my elbow while cleaning up there.

A thin backer material would be preferable to preserve what little head clearance I have inside the van.

I will be using 3M tape under the mounts but being a newb considering adding a bolt through the 2 front mounts for added safety but it would seem at a minimum some thin plywood or other material glued inside would help the roof deforming. I dented it just with my elbow while cleaning up there.

A thin backer material would be preferable to preserve what little head clearance I have inside the van.