Midnight's test put 99A at 165V through a 63A 150V breaker. I think they manually switched it off after 1 second, before the magnetic-hydraulic delay tripped. In one direction it passed, but in the other direction if failed (rather spectacularly)

So that test was 10% over in voltage, 50% over in current.

I think that to interrupt current backflowing into a PV string, it could only work if wired for that polarity (opposite of recommendation). In that case it might be usable as a switch so long as no faults, because would normally have a smaller voltage (just Voc - Vmp) to interrupt. But not necessarily in the event it was feeding a short (Isc followed by Voc).

Wiring two of them in series (opposite polarities) would work up to 150V. Wired in same polarity for 300V, same issue as before.

Midnight has some impressive interrupt ratings (50kA) for their 175A and 250A non-polarized breakers. Obviously something different in the internal construction.

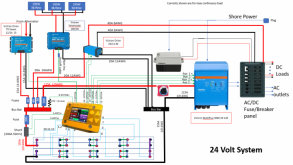

I'm going to class T fuses for catastrophic failures, and breakers for normal overload. Coordinated to let breaker do it's job for up to a few times rated current. That's in my battery bank already, and I'm adding it to grid connection. (PV strings using smaller fuses but similarly high AIC and fast acting).