So I'm just planning out my battery box builds for the new pack.

After doing some winter camping with a crappy shore feed, I knew I had to add some battery heating for the new build.

My batteries live in the unheated compartment of my 5th wheel camper....

The Batteries: 16x 280ah Lifepo4 cells.

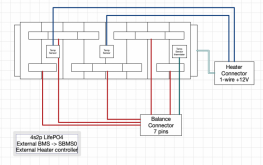

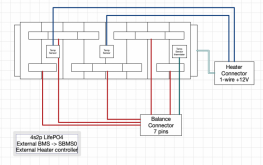

I'm going to build to 12V packs of 8 cells each in a 4s2p configuration.

My BMS will be an electrodacus SBMS0 that will run the full system as a 8s 24v.

I'm going to use 3/4 inch plywood to build the boxes, then brad nails and glue.

Each box will be insulated on all sides and have a heating pad installed in the bottom of the pack.

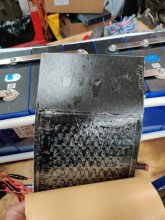

I've decided to use RV water tank heating pads, I ordered these:

I will add a an extra controller to reduce energy usage, but the built in thermostat is reassuring to have.

I put together the packs and measured around 22.5x7 for the pack footprint.

The heater pads are 7.25" x 25", so my boxes will end up just a bit bigger as I think bending these pads is not good.

I'll add some sort of diffuser plate - likely aluminum between the pads and the batteries.

For balance leads, I'm going to use some 22awg silicone insulated wire, with inline fuses at the battery terminals.

To keep wiring sanity, I'll add some connectors on each pack - one for BMS balance leads and one for the heater pads and temp sensors

For temp control, I'll add a pair of one wire DS18B20s and a thermistor to feed the BMS directly.

After doing some winter camping with a crappy shore feed, I knew I had to add some battery heating for the new build.

My batteries live in the unheated compartment of my 5th wheel camper....

The Batteries: 16x 280ah Lifepo4 cells.

I'm going to build to 12V packs of 8 cells each in a 4s2p configuration.

My BMS will be an electrodacus SBMS0 that will run the full system as a 8s 24v.

I'm going to use 3/4 inch plywood to build the boxes, then brad nails and glue.

Each box will be insulated on all sides and have a heating pad installed in the bottom of the pack.

I've decided to use RV water tank heating pads, I ordered these:

Amazon.com: RV Tank Heater Pad | 7 1/4" x 25" | Fresh Water | Gray Water | Holding Tank | Up to 50 Gallons | 12V | with Optional Toggle Switch (3 Pads, No Toggle Switch): Automotive

Buy RV Tank Heater Pad | 7 1/4" x 25" | Fresh Water | Gray Water | Holding Tank | Up to 50 Gallons | 12V | with Optional Toggle Switch (3 Pads, No Toggle Switch): Freshwater Tanks & Inlets - Amazon.com ✓ FREE DELIVERY possible on eligible purchases

www.amazon.com

I put together the packs and measured around 22.5x7 for the pack footprint.

The heater pads are 7.25" x 25", so my boxes will end up just a bit bigger as I think bending these pads is not good.

I'll add some sort of diffuser plate - likely aluminum between the pads and the batteries.

For balance leads, I'm going to use some 22awg silicone insulated wire, with inline fuses at the battery terminals.

To keep wiring sanity, I'll add some connectors on each pack - one for BMS balance leads and one for the heater pads and temp sensors

For temp control, I'll add a pair of one wire DS18B20s and a thermistor to feed the BMS directly.

Last edited: