Hi Yall

I've looked over a few threads on battery enclosures and I think I have a decent idea of how I want to make mine. But I do have a few questions that I'm hoping yall can weight in on. But first, the basic design:

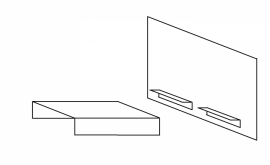

I'll be making an enclosure similar to this one on marinehowto.com. Pictures from that article (I hope it's ok to share them here?):

Since I don't know how they did the small metal bars on the side I'll just use 1/4" threaded stainless steel rods, three on the sides and four on the bottom (though if someone DOES know I'd be curious to hear).

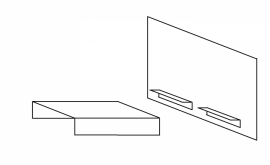

Because I'm concerned that the bottom threaded rods would sag in the middle if they were responsible for supporting the weight of all the batteries, I'll support the weight separately, with aluminum channel. An L-bracket will be bolted to the bottom of the large aluminum side pieces so that it can slip under these channels and essentially allow me to pick up the whole unit without putting the combined weight of the batteries on the backs of the four stainless steel rods on the bottom of the enclosure. The L-bracket won't be bolted or attached to the channel so that it doesn't prevent tightening of the enclosure. I'll try to draw a picture or two.

Here's how I imagine one side of the enclosure with the l-brackets, and the channel that will fit over one of the L-brackets (there would be two pieces of channel in the actual design):

Hopefully you get the picture.

So now the questions:

1) What kind of material should I use for the top? Obiously the top is important as it stops stuff from falling on the batteries, and in the marinehowto example he used plexiglass or something like that. That's great, but the prices I'm seeing on 1/4" thick plexiglass seem a bit spendy, and that's before I find some way to cut it properly with my somewhat limited supply of tools. So I'm wondering about just using some 1/8" aluminum sheet, which will run about $14 or so and can be cut to size at midweststeelsupply.com. But my concern is that aluminum, unlike plexiglass, is conductive. Is this a problem? Is it highly recommended that we use non-conductive materials for the top of the battery enclosure?

PS I should mention that I'll be attaching the top with a hinge...again because I have no idea how the marinehowto person attached their top, it looks like they just popped some nails in to the top like you would when working with wood, but I'm fairly sure that cant be right.

2) Should I protect the sides of the enclosure? My battery enclosure will not, itself, be enclosed. Meaning it won't be in a cabinet like the marinehowto one. Yes, I can face the aluminum plate side out in the direction most likely to get poked with sticks or something, but there's at least some chance that something could get at it from the side. Is it worth getting even more aluminum plate to loosely attach to the sides of the enclosure, just to protect the batteries from damage that way?

3) Water: My battery enclosure will likely be placed near the shower. I'll make sure that no water can splash onto the enclosure, but compared to other parts of the trailer it will be a bit humid for brief periods. Is this a problem?

I've looked over a few threads on battery enclosures and I think I have a decent idea of how I want to make mine. But I do have a few questions that I'm hoping yall can weight in on. But first, the basic design:

I'll be making an enclosure similar to this one on marinehowto.com. Pictures from that article (I hope it's ok to share them here?):

Since I don't know how they did the small metal bars on the side I'll just use 1/4" threaded stainless steel rods, three on the sides and four on the bottom (though if someone DOES know I'd be curious to hear).

Because I'm concerned that the bottom threaded rods would sag in the middle if they were responsible for supporting the weight of all the batteries, I'll support the weight separately, with aluminum channel. An L-bracket will be bolted to the bottom of the large aluminum side pieces so that it can slip under these channels and essentially allow me to pick up the whole unit without putting the combined weight of the batteries on the backs of the four stainless steel rods on the bottom of the enclosure. The L-bracket won't be bolted or attached to the channel so that it doesn't prevent tightening of the enclosure. I'll try to draw a picture or two.

Here's how I imagine one side of the enclosure with the l-brackets, and the channel that will fit over one of the L-brackets (there would be two pieces of channel in the actual design):

Hopefully you get the picture.

So now the questions:

1) What kind of material should I use for the top? Obiously the top is important as it stops stuff from falling on the batteries, and in the marinehowto example he used plexiglass or something like that. That's great, but the prices I'm seeing on 1/4" thick plexiglass seem a bit spendy, and that's before I find some way to cut it properly with my somewhat limited supply of tools. So I'm wondering about just using some 1/8" aluminum sheet, which will run about $14 or so and can be cut to size at midweststeelsupply.com. But my concern is that aluminum, unlike plexiglass, is conductive. Is this a problem? Is it highly recommended that we use non-conductive materials for the top of the battery enclosure?

PS I should mention that I'll be attaching the top with a hinge...again because I have no idea how the marinehowto person attached their top, it looks like they just popped some nails in to the top like you would when working with wood, but I'm fairly sure that cant be right.

2) Should I protect the sides of the enclosure? My battery enclosure will not, itself, be enclosed. Meaning it won't be in a cabinet like the marinehowto one. Yes, I can face the aluminum plate side out in the direction most likely to get poked with sticks or something, but there's at least some chance that something could get at it from the side. Is it worth getting even more aluminum plate to loosely attach to the sides of the enclosure, just to protect the batteries from damage that way?

3) Water: My battery enclosure will likely be placed near the shower. I'll make sure that no water can splash onto the enclosure, but compared to other parts of the trailer it will be a bit humid for brief periods. Is this a problem?