Wow , Amazing

Now Im getting LFP cylindrical @$0.12/wh from china including shipping for que raw cells. I calculated $0.16/wh with everything including busbar holders, barley and fiberglass wrap.

Case & Man hr bring it up to $0.18 / wh

But after seeing your post, BCH has $0.3 / cell 18650. that could change the equation. maybe bringing the cost down to $0.12 wh w/ everything.

It's hard to say exactly - but I agree, I paid (on average with all the discards) more like $1.00-$1.20/cell so $0.30/cell would make a significant difference. The labor to process 12,000 cells (so far) is A LOT but I'm retired/bored so it wasn't a big deal for me. I can see why LifePo4 bricks are popular!!

Cell acquisition is the hardest part. I've found it's best if a 'battery' (~14s100p in my case) is all the same cell type. To get 1,400 good cells I have to more but it's difficult to estimate the keep/discard ratio and then the source is gone if you guess wrong and you don't have enough to do the battery. Then you have to wait....

The only thing holding me back is the Fire risk. even with metal case & fiberglass wrap.

After 4 years of operation - with 10,000 cells in operation and following thousands of posts - fire is not a worry for me because....

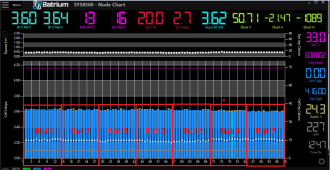

- the cells are BMS'ed with visibility into failing packs so they can be taken offline before serious failure - e.g. its not a 10minute 'thing' but rather multiple days / weeks warning.

- operated in good ambient + cells never get warm (are ambient temp).

- lightly stressed (charge/discharge per cell) - average <100ma/cell with a 400ma/cell max before the master breaker trips - e.g. well within test parameters and the specifications of the cells.

- operating in the middle range (3.5v to 4.0v) for lithium-ion - low stress.

Of course there is some risk, less that taking a drive perhaps, LifePo4 has some risk, lead acid has some risk, but very few things in life are risk free. For me, I believe I'm operating at reduced/acceptable risk thru test/oversizing/low-stress/monitoring/proper-wiring. This is something you have to decide for yourself -

I make no claims, just sharing what I'm doing!

Fire Protection: I have corrugated metal (roofing) over top of the battery bank to block flame from hitting the ceiling, cinder block walls on 3 sides, concrete floor, smoke detector right overhead, and a fire extinguisher - but the 4th side is open to the room.