Isabella Blue

New Member

- Joined

- Jul 1, 2022

- Messages

- 6

Hi battery gurus,

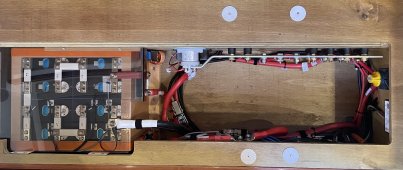

I have been researching replacing the 320Ah SLA’s with LiFePO4 on my sailing boat for a long long time! Why - because an off the shelf battery will not fit the defined space and I have almost given up on trying to purchase individual cells based on people getting ripped off by shady suppliers with no guarantee you will receive the new cells to the specification (endless bad reviews).

I am almost at the point of buying two SLA’s - easy straight forward transaction from one of a thousand reputable suppliers, unfortunately the same cannot be said of LiFeP04!

So - I come to this forum asking for guidance re the purchase of LiFeP04 cells from a reputable manufacturer/supplier. I am looking at a 400Ah system using a combination of cells to fit the defined space and I have narrowed the cells down to Lishen, Winston or EVE. Are any of the cells better for the intended application - installation on a sailing vessel? Who is a reputable supplier?

Any assistance is greatly appreciated.

I have been researching replacing the 320Ah SLA’s with LiFePO4 on my sailing boat for a long long time! Why - because an off the shelf battery will not fit the defined space and I have almost given up on trying to purchase individual cells based on people getting ripped off by shady suppliers with no guarantee you will receive the new cells to the specification (endless bad reviews).

I am almost at the point of buying two SLA’s - easy straight forward transaction from one of a thousand reputable suppliers, unfortunately the same cannot be said of LiFeP04!

So - I come to this forum asking for guidance re the purchase of LiFeP04 cells from a reputable manufacturer/supplier. I am looking at a 400Ah system using a combination of cells to fit the defined space and I have narrowed the cells down to Lishen, Winston or EVE. Are any of the cells better for the intended application - installation on a sailing vessel? Who is a reputable supplier?

Any assistance is greatly appreciated.