Since my ribbon sense cable has 28awg wires, has anyone tried these ring terminals (part # 83-19333 20-18 gauge) on small gauge wire?

Crimp Solder & Seal Ring Terminals

My thinking is that after removing enough sense wire insulation, fold over the bare wire multiple times before inserting it into the heat shrink tube (toward the ring terminal) & then fold over enough insulated wire (behind the bare end) multiple times and insert at the back end of the heat shrink tube (to add some strain relief) before heat shrinking the translucent tube .

These might be better:

26-24 Ga. Heat-Shrink Ring Terminals, 1/4" Stud

26-24 Ga. Heat-Shrink Ring Terminals, 1/4" Stud For use in harsh environments, these terminals feature a heat shrink connection that also has an internal sealant. After crimping the terminal onto the wire, simply apply heat. Keeps moisture out while ensur

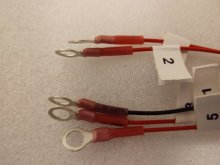

I have used these with 24awg by folding the wire back to double it: