Oliver Luna

New Member

Hello Forum,

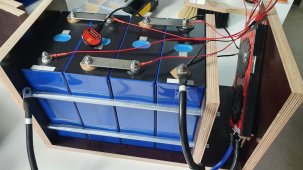

I am a beginner to solar power. Currently I am building an electrical system for a self build camper van.

It consists of 4x EVE lifepo4 280a from basen and a daly BMS 150a. I know the BMS is under powering the batteries. However, I wasn't planning on ever calling on that power either. This setup exists twice to be connected in parallel later on.

I assembled the first system and started it by pressing the Bluetooth button. Everything was wonderful.

When I tried to start the second system in exactly the same way by pushing the button, the BMS immediately started smoking heavily and liquid plastic dripped out.

I had only connected the BMS to the cells with balancer cables, nothing else. I later measured through all the cables and could see that everything was wired correctly.

All identical to the first set which is running great.

Does anyone have any ideas what I could have done wrong?

Thanks a lot!

I am a beginner to solar power. Currently I am building an electrical system for a self build camper van.

It consists of 4x EVE lifepo4 280a from basen and a daly BMS 150a. I know the BMS is under powering the batteries. However, I wasn't planning on ever calling on that power either. This setup exists twice to be connected in parallel later on.

I assembled the first system and started it by pressing the Bluetooth button. Everything was wonderful.

When I tried to start the second system in exactly the same way by pushing the button, the BMS immediately started smoking heavily and liquid plastic dripped out.

I had only connected the BMS to the cells with balancer cables, nothing else. I later measured through all the cables and could see that everything was wired correctly.

All identical to the first set which is running great.

Does anyone have any ideas what I could have done wrong?

Thanks a lot!

![KETO_3P_szerelolap[1].png KETO_3P_szerelolap[1].png](https://diysolarforum.com/data/attachments/59/59844-ff5048dac358c63df33e4e5e066e96c4.jpg)

![124282535.vpAzt13F[1].jpg 124282535.vpAzt13F[1].jpg](https://diysolarforum.com/data/attachments/59/59845-832d9166e88cfb7dcf1028ae41ee8010.jpg)