Here they are considered "structures " so everyone of them gets a rod.NEC doesn't require a ground rod at any signs or pole lights, either. That's the electrical engineers design. (A bad one)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bonding and Grounding Solar Components

- Thread starter fisherus

- Start date

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,452

Yes that would be fine. I don't see any issue with it.Wow, this is one hell of a thread! Lots of distractions.

This quote brings up a concern I have.

My current roof mounted solar has solid, bare #6 from the roof to the MSP and ground bus bar.

Was inspected years ago and in operation currently.

I'm looking to add another roof mounted array.

I was going to join the ground for the new array onto the existing #6 ground in a box close to the arrays and just run the single #6 for both arrays back to the main panel.

Does the NEC specify the need for dedicated ground wires from the PV to the MSP/ground?

Tim, I included your quote above because you mention not starting/stoping the ground which sounds similar to my plan.

I couldn't find any NEC call-out one way or another, but I'm ot the best at finding anything in the code.

If I end up splicing the new array ground onto the original, I'd probably use something like this:

(Unless anyone has a better recommendation)

View attachment 112751

400bird

Solar Wizard

Thanks!Yes that would be fine. I don't see any issue with it.

For some reason I thought I had read a code requiring a unbroken ground from the panels...

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,452

Yes that would be fine. I don't see any issue with it.Wow, this is one hell of a thread! Lots of distractions.

This quote brings up a concern I have.

My current roof mounted solar has solid, bare #6 from the roof to the MSP and ground bus bar.

Was inspected years ago and in operation currently.

I'm looking to add another roof mounted array.

I was going to join the ground for the new array onto the existing #6 ground in a box close to the arrays and just run the single #6 for both arrays back to the main panel.

Does the NEC specify the need for dedicated ground wires from the PV to the MSP/ground?

Tim, I included your quote above because you mention not starting/stoping the ground which sounds similar to my plan.

I couldn't find any NEC call-out one way or another, but I'm ot the best at finding anything in the code.

If I end up splicing the new array ground onto the original, I'd probably use something like this:

(Unless anyone has a better recommendation)

View attachment 112751

The inverter has DC and AC with common connections. (Usually the DC negative to neutral or ground) in many cases AC ripple current is present on the DC circuits. If the DC circuit shorts to ground, the AC circuit providing this current is opened by breaker or fuse.Equipment Grounding Conductor is in the NEC in order to provide a current path back to the transformer neutral, causing a circuit protection device to trip. This is for the AC from the transformer to get back to the transformer. Take that grounding conductor to the array where there is no AC wiring, only ungrounded DC.... and DO WHAT WITH IT? It will not provide a current path back to anything because even if one of the PV wires touches the metal frame, wiring box, or whatever, there is no circuit, no path to anywhere.

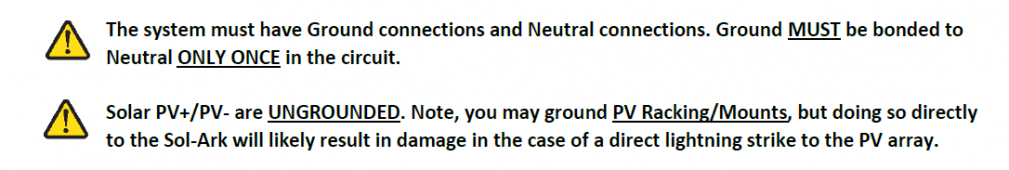

Sol-Ark says it is not grounded on the DC side.Yes that would be fine. I don't see any issue with it.

The inverter has DC and AC with common connections. (Usually the DC negative to neutral or ground) in many cases AC ripple current is present on the DC circuits. If the DC circuit shorts to ground, the AC circuit providing this current is opened by breaker or fuse.

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,452

That's because the engineer wants it. Not because it's required by NEC. The same thing is happening here. Because "that's how it's always been done ".Here they are considered "structures " so everyone of them gets a rod.

Anything made of metal and sticking up in the air.

The actual ground rod serves no purpose. The pole is attached to large anchor bolts that are encased in concrete. Which is a much better connection to the earth. This is better for static and lighting mitigation. But the grounding conductor is the only protection from electrical Hazzard.

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,452

It's connected through the AFCI and GFCI inside the Sol-Ark. This is in regard to the DC circuit conductors.Sol-Ark says it is not grounded on the DC side.

View attachment 112821

You should never bond either. (Exception: battery negative in a mobile application)

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,452

Not required, but recommended. Just not always feasible.Thanks!

For some reason I thought I had read a code requiring a unbroken ground from the panels...

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

There are two purposes to the Equipment Grounding Conductor.Equipment Grounding Conductor is in the NEC in order to provide a current path back to the transformer neutral, causing a circuit protection device to trip. This is for the AC from the transformer to get back to the transformer. Take that grounding conductor to the array where there is no AC wiring, only ungrounded DC.... and DO WHAT WITH IT? It will not provide a current path back to anything because even if one of the PV wires touches the metal frame, wiring box, or whatever, there is no circuit, no path to anywhere.

1) Low impedance path clear a fault. (This is why the N-G bond is part of the EGC system.)

2) Ensure equipment does not float to a potential significantly higher than that of the earth. (This is why the Grounding Electrodes are part of the EGC system)

Having said that, I agree that the EGC requirement for the PV wiring is hard to rationalize and touches on something I have yet to figure out.

The NEC requires any DC circuit running above 50V to have a grounded conductor (Neutral). This means there should be a DC equivalent to an N-G bond. However, in practice, it seems like this is rarely done for PV circuits. In fact, many (most?) solar controllers specifically say not to do it. Is there some kind of exception in the NEC for PV circuits? Even if there is a grounded conductor on the PV circuit, it would not necessarily clear a ground fault. The way the wiring and fusing requirements are set up, you could have a 500V PV circuit with no fuse or breaker on it.

There is a requirement for PV ground fault protection that is enforced by most inspectors. With ground fault protection in place, if one of the PV current carrying conductors were to short to the metal mount, the ground fault protection device would disconnect the PV..... but that does not necessarily clear the fault (the PV does not turn off). For this function, the NEC wants the ground reference to be the house EGC, so it does make sense that the EGC needs to go to the array.

The bottom line is this: We can debate whether the requirement makes sense..... but the requirement is there either way.

Last edited:

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Where is 'here'?Here they are considered "structures " so everyone of them gets a rod.

So back to my statement.....anyIt's connected through the AFCI and GFCI inside the Sol-Ark. This is in regard to the DC circuit conductors.

You should never bond either. (Exception: battery negative in a mobile application)

FilterGuy, thanks for the information. I have spoken to the guy that will inspect and he said it is okay to run a #6 outside my DC conduit, in the same trench. So from the house ground to the array frame then to my PV surge suppression......is my current plan. Maybe the bare wire in the 300feet of earth will give any potential nearby lightning strike a chanced to be attenuated rather than conducted (with insulation) to the house ground.There are two purposes to the Equipment Grounding Conductor.

1) Low impedance path clear a fault. (This is why the N-G bond is part of the EGC system.)

2) Ensure equipment does not float to a potential significantly higher that of the earth. (This is why the Grounding Electrodes are part of the EGC system)

Having said that, I agree that the EGC requirement for the PV wiring is hard to rationalize and touches on something I have yet to figure out.

The NEC requires any DC circuit running above 50V to have a grounded conductor (Neutral). This means there should be a DC equivalent to an N-G bond. However, in practice, it seems like this is rarely done for PV circuits. In fact, many (most?) solar controllers specifically say not to do it. Is there some kind of exception in the NEC for PV circuits? Even if there is a grounded conductor on the PV circuit, it would not necessarily clear a ground fault. The way the wiring and fusing requirements are set up, you could have a 500V PV circuit with no fuse or breaker on it.

There is a requirement for PV ground fault protection that is enforced by most inspectors. With ground fault protection in place, if one of the PV current carrying conductors were to short to the metal mount, the ground fault protection device would disconnect the PV..... but that does not necessarily clear the fault (the PV does not turn off). For this function, the NEC wants the ground reference to be the house EGC, so it does make sense that the EGC needs to go to the array.

The bottom line is this: We can debate whether the requirement makes sense..... but the requirement is there either way.

John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

Its my understanding that most solar charge controllers are non-isolated so if you reference the core of the dc system to the planel, the pv array is also referenced.Sol-Ark says it is not grounded on the DC side.

View attachment 112821

Not sure about the Sol-Ark.

To test you this, before you connect the Sol-Ark to anything else check for continuity between battery negative and pv negative.

I'm sure you know that, just consider me Basil Exposition.

I'm guessing there are many systems in the field that have the dc busbar referenced to the planet.

Samsonite801

Solar Wizard

- Joined

- Oct 15, 2020

- Messages

- 2,988

A rod at the array is a good thing, in my opinion.

This keeps the array at the same zero potential as the earth around it.

Based on some recent investigation I've been doing regarding grounding of solar arrays (and say, satellite or outdoor wifi / telecom equipment towers).

The is some strong evidence I've been seeing, indicating that fully grounding towers and solar array ground mounts to a copper ground rod could help to attract lightning strikes into these locations.

Just to sum it all up in short form. I am finding that lightning/surge arrestors inline with the PV circuit conductors' run (and grounded to a copper ground rod at the array or tower location) is a great thing.

But grounding the array mount / solar panel chassis to Earth, may not be as desirable. My thought is to perhaps leave the array ungrounded and try to insulate it from ground (or just leave it at whatever Earth-ground delta it already is at), and use a resistor between the actual ground rod and insulated or semi-insulated array (to help keep voltage potential at zero or close to it, like from wind and static electricity buildup), but not actually providing a solid 0 Ω ground.

Obviously, there are a lot of metal-based ground mounts which would be naturally grounded to various degrees anyways, so this may not be easy to control (to insulate the ground mount or tower).

It could simply be more effective to place lightning rods at other locations on the property in question, to help draw lightning strikes away from the tower or array location (and just allow to fully ground those fixture arrays).

I do know that when we used to build WISP towers (at an old job I had), we would generally ground towers, but not chassis ground the radios themselves to the tower chassis (as they had plastic housings anyways). But we'd use shielded CAT5/6 cables which would carry the equipment circuit board grounding, to connect through the ethernet cable shield, which would go down to the Ethernet surge protection devices on the ground, which have their own Earth grounding connection to the ground rod, but towers themselves would ground on a separate path.

I don't have all the answers yet in planning for my own ground mount install I will be doing soon. I definitely know it is true what you say that we want to keep that zero potential, but also, can we design the system in a way as in not to help encourage lightning strikes towards our equipment? Would it be better to use a resistor in these cases to allow most voltage deltas (between equipment chassis ground and Earth ground) to balance out, without creating a 0 Ω connection from array chassis to Earth ground?

Or in my case, my array mount will be around eye level height (right next to my steel building), which my steel building will be a much taller structure. I wonder if putting lightning rods on the peak of the building ridge (away from the array), or to build actual lightning rods towers on the ends of the property would be more effective at keeping lightning away from the arrays and structure. We do get violent lightning here and it is a fairly empty valley (no trees or other buildings by me), where I worry a bit about being one of few lots in an open field (with metal conductor all over it).

Or is it even in my power at all to try and control somewhat what the lightning will do hehe...

Last edited:

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,452

I have removed the previous post that you quoted.Based on some recent investigation I've been doing regarding grounding of solar arrays (and say, satellite or outdoor wifi / telecom equipment towers).

The is some strong evidence I've been seeing, indicating that fully grounding towers and solar array ground mounts to a copper ground rod could help to attract lightning strikes into these locations.

Just to sum it all up in short form. I am finding that lightning/surge arrestors inline with the PV circuit conductors' run (and grounded to a copper ground rod at the array or tower location) is a great thing.

But grounding the array mount / solar panel chassis to Earth, may not be as desirable. My thought is to perhaps leave the array ungrounded and try to insulate it from ground (or just leave it at whatever Earth-ground delta it already is at), and use a resistor between the actual ground rod and insulated or semi-insulated array (to help keep voltage potential at zero or close to it, like from wind and static electricity buildup), but not actually providing a solid 0 Ω ground.

Obviously, there are a lot of metal-based ground mounts which would be naturally grounded to various degrees anyways, so this may not be easy to control (to insulate the ground mount or tower).

It could simply be more effective to place lightning rods at other locations on the property in question, to help draw lightning strikes away from the tower or array location (and just allow to fully ground those fixture arrays).

I do know that when we used to build WISP towers (at an old job I had), we would generally ground towers, but not chassis ground the radios themselves to the tower chassis (as they had plastic housings anyways). But we'd use shielded CAT5/6 cables which would carry the equipment circuit board grounding, to connect through the ethernet cable shield, which would go down to the Ethernet surge protection devices on the ground, which have their own Earth grounding connection to the ground rod, but towers themselves would ground on a separate path.

I don't have all the answers yet in planning for my own ground mount install I will be doing soon. I definitely know it is true what you say that we want to keep that zero potential, but also, can we design the system in a way as in not to help encourage lightning strikes towards our equipment? Would it be better to use a resistor in these cases to allow most voltage deltas (between equipment chassis ground and Earth ground) to balance out, without creating a 0 Ω connection from array chassis to Earth ground?

Or in my case, my array mount will be around eye level height (right next to my steel building), which my steel building will be a much taller structure. I wonder if putting lightning rods on the peak of the building ridge (away from the array), or to build actual lightning rods towers on the ends of the property would be more effective at keeping lightning away from the arrays and structure. We do get violent lightning here and it is a fairly empty valley (no trees or other buildings by me), where I worry a bit about being one of few lots in an open field (with metal conductor all over it).

Or is it even in my power at all to try and control somewhat what the lightning will do hehe...

I no longer feel that is a good idea. I came up through the trade, learning from my mentors. I have learned over the years that they were wrong about some things. And the people that I have trained in the past will say the same, at some point. I learn new things all of the time. And am happy to do so. Repeating what you have heard for many years is easy. Understanding how electricity works, changes how you look at it.

Samsonite801

Solar Wizard

- Joined

- Oct 15, 2020

- Messages

- 2,988

I have removed the previous post that you quoted.

I no longer feel that is a good idea. I came up through the trade, learning from my mentors. I have learned over the years that they were wrong about some things. And the people that I have trained in the past will say the same, at some point. I learn new things all of the time. And am happy to do so. Repeating what you have heard for many years is easy. Understanding how electricity works, changes how you look at it.

I too, find that my learning (in every aspect) is constantly evolving. The coolest part is that I could have the courage to find (could apply to all of us hehe), that I can stay open-minded enough (as you are) to be able to re-write and update my knowledge (to not get too stuck in my old thought patterns), to be able to admit to self that perhaps things could be different than I had previously thought (and, how many people I may have taught that idea to). I'm not saying I fully understand how electricity works by any means, but I try to 'think like the electricity' does, which can hopefully help to get me closer to a better understanding.

I recently also just learned a few months ago, that there is a difference between positive and negative polarity lightning strikes too. That kind of added another dynamic to things as well for me in my thinking hehe...

I had been trying to search about which direction a DC spark/arc really travels (in order to see if I could understand if the spark/arc visually can illustrate the flow of the charge/current, or the flow of electrons, as in conventional theory vs electron theory, respectively), so I was trying to imagine like a spark plug in an internal combustion gasoline engine to see if I could understand if the spark is really jumping from ground to the electrode (per electron flow theory, where it is known that the electrons are traveling from negative to positive to fill in the holes), or does the spark really originate from the electrode-side and where the voltage/current/charge is traveling to ground (as we may assume it does with conventional theory).

So that evolved into looking at lightning (since it has to bridge a much larger gap, perhaps it could help me understand which way the spark/arc travels due to traveling much larger distances), maybe it would be more apparent to see with the naked eye (since the spark/arc is trying to travel across great distances at speed of light). So then that led into finding out that lightning can strike with either polarity hehe.

Later, I found this post (and some others), which seem to suggest that the spark/arc may actually originate from both ends during the ionization:

Which way does a high voltage spark jump?

Hello All! Quick question... When a high voltage capacitor is charged to say 3000 volts, a spark will jump across the terminals. Does the spark jump from the positive to negative terminal, or from negative to positive? Thanks Very Much! Bill

So maybe we will never know all the details, or maybe it will take generations more before humanity fully understands electricity hehe. I'm trying to figure out what science already knows, and what I think I know, and what is actually true, which is like trying to catch a slippery fish with your bare hands sometimes.

Last edited:

Well I'm better educated after reading through all this, but still confused as to the best way to handle my own installation, so any suggestions would be appreciated!

My DC coupled panels are going on a detached garage, which is about 50' (at the closest points) from the house (where my main ground, service, and inverter is located). In between, I plan on having a row of AC coupled PV panels mounted on a wooden fence. Currently only a single ground located at the house and it's 80' from the closest point of the garage, or about 110' from the backside of the garage, which is where I was previously considering installing a second ground for the DC coupled frames.

What's the best way to handle all of this, including grounding the AC coupled panels in between? The inverter is a SA15k, so while I plan on using it mostly offgrid, it will occasionally be used on-grid as well.

TIA!

My DC coupled panels are going on a detached garage, which is about 50' (at the closest points) from the house (where my main ground, service, and inverter is located). In between, I plan on having a row of AC coupled PV panels mounted on a wooden fence. Currently only a single ground located at the house and it's 80' from the closest point of the garage, or about 110' from the backside of the garage, which is where I was previously considering installing a second ground for the DC coupled frames.

What's the best way to handle all of this, including grounding the AC coupled panels in between? The inverter is a SA15k, so while I plan on using it mostly offgrid, it will occasionally be used on-grid as well.

TIA!

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,452

Simple explanation:Well I'm better educated after reading through all this, but still confused as to the best way to handle my own installation, so any suggestions would be appreciated!

My DC coupled panels are going on a detached garage, which is about 50' (at the closest points) from the house (where my main ground, service, and inverter is located). In between, I plan on having a row of AC coupled PV panels mounted on a wooden fence. Currently only a single ground located at the house and it's 80' from the closest point of the garage, or about 110' from the backside of the garage, which is where I was previously considering installing a second ground for the DC coupled frames.

What's the best way to handle all of this, including grounding the AC coupled panels in between? The inverter is a SA15k, so while I plan on using it mostly offgrid, it will occasionally be used on-grid as well.

TIA!

Everything above grade should be bonded together.

Everything below grade should be bonded together.

The two should bond together at one point. (Usually the main service panel)

Samsonite801

Solar Wizard

- Joined

- Oct 15, 2020

- Messages

- 2,988

Well I'm better educated after reading through all this, but still confused as to the best way to handle my own installation, so any suggestions would be appreciated!

My DC coupled panels are going on a detached garage, which is about 50' (at the closest points) from the house (where my main ground, service, and inverter is located). In between, I plan on having a row of AC coupled PV panels mounted on a wooden fence. Currently only a single ground located at the house and it's 80' from the closest point of the garage, or about 110' from the backside of the garage, which is where I was previously considering installing a second ground for the DC coupled frames.

What's the best way to handle all of this, including grounding the AC coupled panels in between? The inverter is a SA15k, so while I plan on using it mostly offgrid, it will occasionally be used on-grid as well.

TIA!

Another good point to look at is surge arrestors, what they do, and how they operate to help protect equipment (which involve grounding as well):

Example:

That's because the engineer wants it. Not because it's required by NEC. The same thing is happening here. Because "that's how it's always been done ".

Anything made of metal and sticking up in the air.

The actual ground rod serves no purpose. The pole is attached to large anchor bolts that are encased in concrete. Which is a much better connection to the earth. This is better for static and lighting mitigation. But the grounding conductor is the only protection from electrical Hazzard.The 2017 code was amended in attempt to define

Nevada , AZ. In 2017 the Nec was amended to attempt to take some of the speculation about what is considered a structure. A light pole has been given an exemption if the pole is a manufactured part of the lighting system .Where is 'here'?

Billboards , electric signs, airfield towers etc... anything with an on site built metal support is a structure .

Similar threads

- Replies

- 7

- Views

- 195

- Replies

- 28

- Views

- 2K

- Replies

- 51

- Views

- 1K