neil_99

New Member

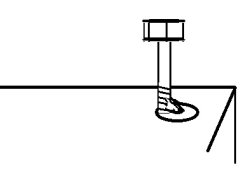

So, I used too much torque on one of my welded studs on my Eve batteries. It broke off near the bottom. I've attached a picture. How do I fix this? Do I drill out the stud and tap a new larger thread in the terminal? I don't have much experience tapping threads. Would I be better off just buying another cell?