Hello,

first post in this amazing forum.

I am an EE addicted to TEA, but I am trying to get up to speed with batteries and solar system.

I ordered the following for my home in USA:

I hired a solar company that will take care about the roof PV installation.

The first question I have is where I can buy copper bus bars for the batteries, moreover I can't find any design rules for the ampacity.

As you probably already have guessed, my final battery will be a 48V 840Ah (=280Ahx3) monster, and I would like to get the right busbar for it.

The first obstacle I found in my design is what are the required bus bars dimensions for those battery terminals.

Sure I could use some 4/0 cable, but I think a bus bar is the right trigger to pull in this case.

Yes I am crazy my first system will be at my home and it is not a small one IMHO.

Many thanks in advance for your kind help.

first post in this amazing forum.

I am an EE addicted to TEA, but I am trying to get up to speed with batteries and solar system.

I ordered the following for my home in USA:

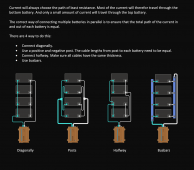

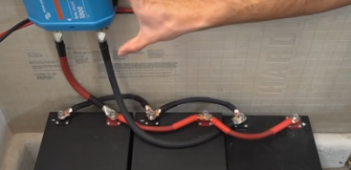

- #48 EVE 280AH, planning to use them as 48V system 3Px16S

- #3 Victron Energy MPPT Smartsolar 450-100

- #2 Victron Energy Quattro 10KVA 120VAC for Splitphase generation

- Other Victron Energy devices... Cerbo and so on

I hired a solar company that will take care about the roof PV installation.

The first question I have is where I can buy copper bus bars for the batteries, moreover I can't find any design rules for the ampacity.

As you probably already have guessed, my final battery will be a 48V 840Ah (=280Ahx3) monster, and I would like to get the right busbar for it.

The first obstacle I found in my design is what are the required bus bars dimensions for those battery terminals.

Sure I could use some 4/0 cable, but I think a bus bar is the right trigger to pull in this case.

Yes I am crazy my first system will be at my home and it is not a small one IMHO.

Many thanks in advance for your kind help.