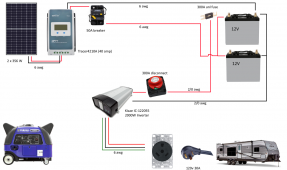

Hello everyone, I am building a system for my 29 foot trailer and I believe I have most of it figured out but I do have some questions.

I plan on starting with the following parts

-KISAE IC-122055 INVERTER-CHARGER 55 AMP

-EPever 4210A 40 AMP

Rated Charge Power 520W/12V 1040W/24V

Max. PV Array Power 780W/12V 1560W/24V

-1x Canadian Solar CS3K-315MS 315w panel

-2x GS GC 225 Ah batteries

First question is for the solar panel and the charge controller, do I use the rated charge power or Max PV Array when calculating and do I use the 12v or 24? The solar panel datasheets shows that it runs at Vmp 33.1v and Voc 39.9v. Will the panel i selected work correctly and I wanted to have enough room to add a second panel.

Second question is how to you calculate the wire size between the devices and what size of fuse you require?

I plan on starting with the following parts

-KISAE IC-122055 INVERTER-CHARGER 55 AMP

-EPever 4210A 40 AMP

Rated Charge Power 520W/12V 1040W/24V

Max. PV Array Power 780W/12V 1560W/24V

-1x Canadian Solar CS3K-315MS 315w panel

-2x GS GC 225 Ah batteries

First question is for the solar panel and the charge controller, do I use the rated charge power or Max PV Array when calculating and do I use the 12v or 24? The solar panel datasheets shows that it runs at Vmp 33.1v and Voc 39.9v. Will the panel i selected work correctly and I wanted to have enough room to add a second panel.

Second question is how to you calculate the wire size between the devices and what size of fuse you require?