brandnewb

Going for serious. starting as newb

also I am going to need a more fine tuned scale as I have already met the limits of it. when it only reads ERROR (meaning too much force)

View attachment 75014

at +-25mm distance the opposing force was +- 241g(gram)

at +-15mm distance the opposing force was > 550g

I'll admit that this test was mostly manual and thus giving my trademark earthshaker hands not reliable at all.

Any closer and I would repell the whole setup over,.

yes and you lot are still enjoying the resultsWe who overthrew the crown use "pounds" for both weight and force.

yes sir, i'll build a segment of an alternator.That's why I suggest building a segment of a motor, with magnets swinging on an arm past one coil of the armature, and measuring stall torque vs. current.

not yet, but I have read about some some open source ones using ardiuno or comparable. I like open sourceIf you have an oscilloscope

Behemoth (C)P.S. 96 magnets is ok for the size of your design. Your 0.82m rotor is a behemoth!

I do have an indoor pool I built myself. minimum temp is 37 degrees C. Maybe that will help motivate to join the contest.If you don't have a sauna on your property, what are you doing with your life? Work on the sauna FIRST, then get back to the wind turbine. Prioritize!

regarding the enamled copper in a coil. And ignoring the skin effect in large diameter single core coils. Does it only matter how much of copper there is in a coil? or is it the total length of the wire in a coil i.e. smaller wires multi turns?

Because I could measure the exact length a full 360 coil phase path and cut the wires to length. Then combine them in a twisted manner like a litz wire. it would shorten the war by 5 years and safe millions of lives if that would make sense to do.

currently I have prepared a single loop +- 71m 1mm, pre twisted into 16 strands. It's hard to do and the result is sloppy

Also, one should assume there will be coils where one magnet is covering strands that run in opposite directions. Is that a problem if the coil wires need to be a closed loop?

8.5mm you fathom? Say no more, I'll get me a mile of that diameterI don't think Litz will help with anything. I don't think skin effect will come into play. At 60 Hz, skin depth is 8.5 mm, an your wires are so much smaller it doesn't matter.

lol, not assume, it's a given as each adjacent wire is contraregarding the enamled copper in a coil. And ignoring the skin effect in large diameter single core coils. Does it only matter how much of copper there is in a coil? or is it the total length of the wire in a coil i.e. smaller wires multi turns?

Because I could measure the exact length a full 360 coil phase path and cut the wires to length. Then combine them in a twisted manner like a litz wire. it would shorten the war by 5 years and safe millions of lives if that would make sense to do.

currently I have prepared a single loop +- 71m 1mm, pre twisted into 16 strands. It's hard to do and the result is sloppy

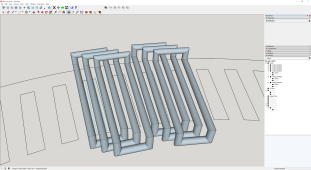

View attachment 75231

Also, one should assume there will be coils where one magnet is covering strands that run in opposite directions. Is that a problem if the coil wires need to be a closed loop?

I meant after winding a single phase for 360 degree with a single strand then not stop there. just go as go on until I almost meet the next planed phase coil space.2) one full 360 degree 96 coils wind, and while I am at it complete it to maximum.