HighDesertOffgrid

Solar Addict

- Joined

- Sep 15, 2022

- Messages

- 628

There are more clues to the success of this mission here:We're gonna need more bricks!

(Extend pole taller, and use guy wires to anchors.)

There are more clues to the success of this mission here:We're gonna need more bricks!

(Extend pole taller, and use guy wires to anchors.)

I am not sure about your intend. can you please elaborate?There are more clues to the success of this mission here:

Levity. I expect the poster was repurposing a line from the Movie "Jaws" (probably lost to you) for comedic impact. I suppose it may be seen as a "weird" reply for some. Are you easily offended?yes redundant indeed. I have even tried to contact rossie way back based on that video. But as one might have guessed she did not feel our work here is important enough to reply. Or maybe she never got the email. spam filters are nasty these days.

Also one does not need to insert weird messages into threads in order to be able to follow them. So I kindly ask again. What was your intend?

*) especially since I realized the magnets will be equally attracted by coils under load from both sides. Essentially resulting in 0 bending on the disk.

Until someone shoots a hole in this reasoning I am going to focus again on getting a good solid magnet disk. We need some numbers by nowBlow up some car lights even with this alternator.

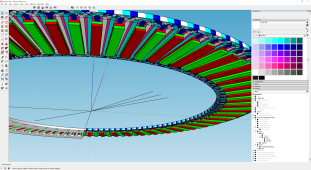

Finally found some time to make a schematic drawing of one of the stators a.k.a. coil disk.

View attachment 110888

the dark red slab at the bottom is a 10mm high disk of iron powder to attract the magnetic field to pass through the coils (that are not shown yet)

the pinkish/purplish fans on top of that are coil separators printed using iron powder filled filament

View attachment 110890

here we can see the 3 phases of coils.

Regarding coging. if it was a electro motor it would be a huge problem as there are as many coils per phase as there are poles.

However, this is a generator and the wind charge controller does not put a load on the coils before the voltage has reached 48 volts and the controller will short the coils if the voltage becomes greater than 56 volts.

Should I worry about coging and if so can anyone suggest a way on how to reduce that?

Also please keep in mind that there will be 2 coil disks. 1 on each side of the magnet disk.

I am guessing (a slightly educated guess that is) that a coil under load and a PM (permanent magnet) passing past it (as in a PM alternator while in operation) will experience an attractive force coercing them towards the PMs.Now I'm confused which direction with magnet passing coil of wire. It must be dragging wire after it, at least once beyond the wire?

There is no easy answer.Are you easily offended?

I'm still watching. I have to be honest, after our initial conversation, I did try to read the entirety of this thread, but gave up around page 25. So, I'm not sure of your progress and have little to offer.@HighDesertOffgrid

still love you. don't be shy.

thank you!I'm still watching

@justgary the arcs at the corners is to reduce warping. thus far it seems to help indeed.@HighDesertOffgrid

still love you. don't be shy.

I have got some exciting update

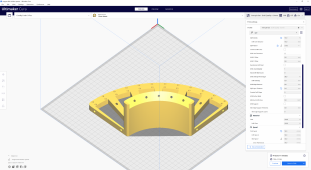

View attachment 113940

this is what we call a magnet disk holder.

It should not really matter what material the damned thing is printed with as chances are the heat build up wont be that great (@Hedges suggested as such, granted this was while very few context was available) around this aspect of the alternator.

But then again pay close attention to the holes that are angled at 45 degrees from the plane.

you might wonder "but why my most dearest brand of newbs"

Well, so we can have m4 threads fortify the whole damned thing.

It's taking ages with trail and error to get prints to come out how they need to be. But fear not. Trail and error is what I excel at.

@justgary , @curiouscarbon I am now finetuning the first layer with a Z yes a ZET, not a ZEE hahahha) axix offset within Cura. not ideal but it does seem to work until now.

Here is another question for one?

How many watts does a 12v carlight need to blow up? Yes, you've guessed it. that is what we are gonna do!!!

I know what you mean. I recently finished printing nine cover plates for my batteries. Each one is fairly large and has a lot of contact with the PEI build plate. I ruined the first one trying to remove it (even after putting it in the freezer). I then adjusted the Z (zee, not zet or zed!) height to get it sticking yet easy enough to remove. Each one took about 16 hours to print.@justgary the arcs at the corners is to reduce warping. thus far it seems to help indeed.

Also I have once again went into my pockets and ordered one of those PEI plates for this printer. It's not cheap but hopefully it will help reduce warping and the fights I have getting prints of this stock glass build plate

ok brother, only now I saw you need more details in order to be able to add anything useful.If it does have attraction, mid-point is an astable equilibrium.

Repulsive, it should be stable.

Now I'm confused which direction with magnet passing coil of wire. It must be dragging wire after it, at least once beyond the wire?

Permanent magnets, we know how those would behave.

hahahhaReducing the vertical distance from the carriage to the cutter would help a lot. Even shortening the cutting tool would help. More distance is more lever arm for the force to try to rotate the assembly. Reducing cutting speed is your only other choice so the cutter has less force on it.

Sometimes life is just like that. It could be why I never get anything done.so I will need a dremel cutting disk to cut down a dremel routing tool.

does one see the circular nature here?