John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

What kind of wire and what awg?cuts cable like butter. Cuts so smoothly I wish I could use it more.

Big difference between welding cable and xhhw.

What kind of wire and what awg?cuts cable like butter. Cuts so smoothly I wish I could use it more.

I have the smaller version of that, and it cuts like butter.What kind of wire and what awg?

Big difference between welding cable and xhhw.

I doubt the product description can tell me what type of wire at what gauge you were cutting so smoothly.take a minute out of your busy day and maybe look at the product instead of upping your post count.

cuts cable like butter. Cuts so smoothly I wish I could use it more.

This is 2/0 welding cableI should have provided more context with my post. I'm typically cutting 2/0 or 6 gauge cable. A cutting die for the hydraulic crimper would allow me to easily cut 2/0 cable using the same tool that I use for crimping with a lot less effort than a set of pliers-like cutters can. I have a set of Klein cutters rated to 2/0 and they really struggle to cut 2/0, but work well with 6 gauge.

This is 2/0 welding cable

Conductor Strand: 1248/30

2/0 Welding Cable Class K

2/0 Flexible Welding Cable - 600V. Cut to length and sold by the Foot.www.wireandcableyourway.com

This is 2/0 xhhw-2

Number of Strands: 19

2/0 XHHW Building Wire

XHHW Stranded Building Wire. Cut to length - sold by the Foot.www.wireandcableyourway.com

A tool that will cut through welding cable like butter may dull or break on xhhw-2.

Which is as it should be because your application is mobile.All my DC cable is welding cable.

I like the TH1818. I have done dozens of crimps, with everyone coming out fine.Nobody answered my post about the 3 point crimper with an electric impact. So much cheaper than the Temco

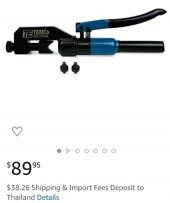

I should have given some context. It's the total cost inc ship and tax to Thailand.I like the TH1818. I have done dozens of crimps, with everyone coming out fine.

At $90, you get to decide if your $57 is so much cheaper. I would buy the TH1818 again.

One is faster to use, and likely more reliable… and priced accordingly.I should have given some context. It's the total cost inc ship and tax to Thailand.

Very surprised to see the TH1818 hydraulic is cheaper than the TH0012 manual though. Saves me buying an electric impact driver for the little one.

View attachment 104697

View attachment 104698

View attachment 104696

I assume you are dissing the TH1818. While I haven't used the TH0012, from what I have studied and watched on YouTube, I doubt that it would provide the feel of the crimp being fully formed that I get with the TH1818. The indent mechanism looks identical.One is faster to use, and likely more reliable… and priced accordingly.

this is basically the same thing I use, but mine was made during the Vietnam conflict and sold to the US navy as an aircraft cable crimper (stainless fittings and cables) so when I do copper with it or tinned copper fittings I get OF crimps. I got it many years ago and its still going strong. mine has a tang that hangs down to grab with a 14" vice so that it is immobile while using. you can also use it free hand but when in the vice your crimps are very precise.I like this one much better.

Will recommended it in some of his battery builds, and I use it on my bigger projects.

So much faster than hydraulic.

great for one offs and non production, but from a time and cost standpoint the threads will wear out unless you religiously lubricate it with the proper weight grease for the amount of force it must convey to the crimp point. if you have less than a couple hundred crimps it is a cost positive too,IE does not pay for itself.Nobody answered my post about the 3 point crimper with an electric impact. So much cheaper than the Temco

I didn't find much use for the "recommended pumps." It seemed too arbitrary to me as there is a range on terminals and wire.@BobCollins did you find the recommended pumps way off? I recently picked up the TH1818 and find I'm using 12-13 pumps vs the 'recommended' 8 for 1awg