I know there are quite a few BMS out there that I can purchase. And I did try that route. Purchased a 300A and 100A Chargery BMS. Chargery did not meet my expectations. I feel that I can do better than that. So here I am. Most likely won't use my creation as I'm sure there are better units out there being designed. This may just be an exercise to keep my mind from decaying to rapidly.

The main problem with Chargery is

1. the inability to measure current within the range +/- 1A

2. current resolution is not adequate.

The result is that SOC is woefully inaccurate.

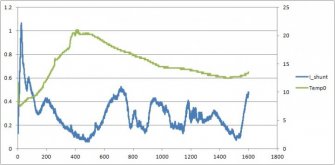

I've already tackled current measurements and a coulomb counter in this thread:

https://diysolarforum.com/threads/coulomb-counter-for-diy-bms.11610/

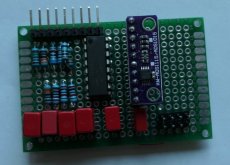

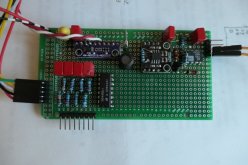

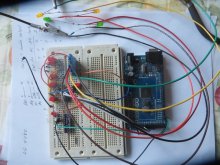

All that's left is cell voltage management. Here's my first attempt at proof of concept.

I didn't want to pull the LiFePO4 12V battery out of the vehicle just yet, so the yellow and green led network simulate the 4 cell voltages.

The circuit is simple:

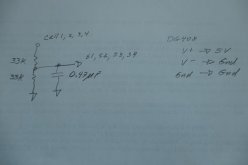

4 resistor divider networks with filter cap

1 DG408D multiplexer

1 ADS1115 16-bit A/D

1 Arduino Mega (right now) will switch to Nano later

Powered it up and it appears to work OK.

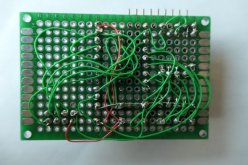

Next step is to solder it up and run some tests.

More to come.

The main problem with Chargery is

1. the inability to measure current within the range +/- 1A

2. current resolution is not adequate.

The result is that SOC is woefully inaccurate.

I've already tackled current measurements and a coulomb counter in this thread:

https://diysolarforum.com/threads/coulomb-counter-for-diy-bms.11610/

All that's left is cell voltage management. Here's my first attempt at proof of concept.

I didn't want to pull the LiFePO4 12V battery out of the vehicle just yet, so the yellow and green led network simulate the 4 cell voltages.

The circuit is simple:

4 resistor divider networks with filter cap

1 DG408D multiplexer

1 ADS1115 16-bit A/D

1 Arduino Mega (right now) will switch to Nano later

Powered it up and it appears to work OK.

Next step is to solder it up and run some tests.

More to come.