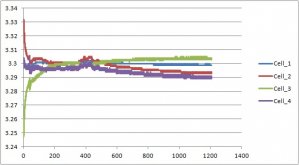

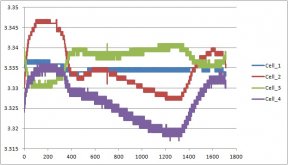

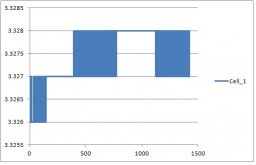

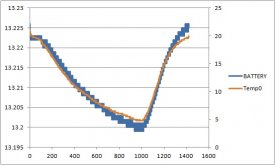

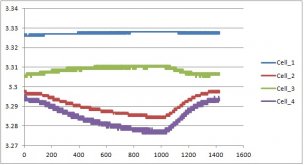

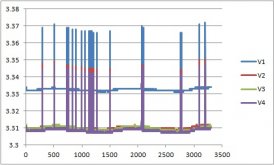

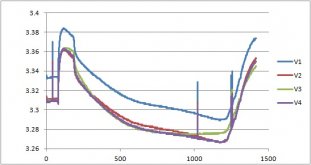

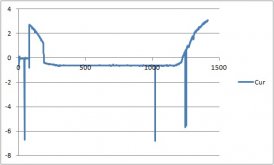

This plot shows cell 1 (scale to left) and cell 4 (scale to right) voltage with respect to ground. Everything looks fine the first 600 minutes (10 hours). Not sure what's going on after that. Perhaps a common bad connection? At around 1200 minutes, measurements totally flip out, both going to max readings. It sure looks like a connection/signal is lost.

Resistor going intermitent maybe? or just a bad connection?

What is your Vref for the voltage measurement? same one as for the current one?

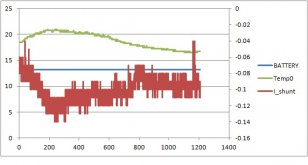

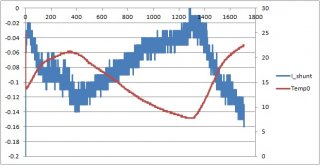

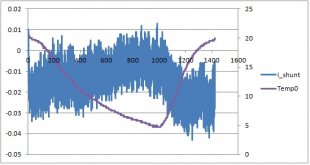

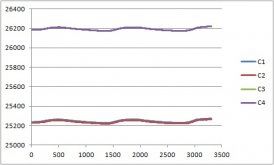

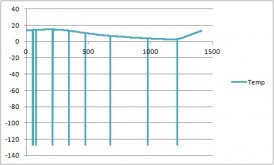

This plot show shunt current (which is shorted together at the circuit board) with scale to the right, and temperature with deg.C scale to the right. I'm not sure why the current is moving around like that. At least current is not totally flipping out around the 1200 minute mark. Current measurement and cell voltage measurements use the same adc1115. Both measurements use differential inputs.

Given there's around 109 LSB/A and the drift is around 1 A p-p it's very unlikely the problem comes from the ADC. My bet is on the op-amp offset drift and/or the Vref drift. 100 LSB would be 0.2 mV and the Vos of the op-amp is right around that value. The Vref specs are far better so I'd exclude it, not likely to be part of the problem.

Where did you source the components from? because if it's not from a reputable seller you may have some counterfeit components, or factory rejects, or crappier components rebadged as better ones, not meeting the specs in either case.