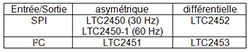

I have the LTC2452 on order. Don't know the difference between 2450 and 2452. They both use 3-wire SPI

I just checked and found this:

So basically they're the same except the 2450 is single ended while the 2452 is differential. Well, funny story, I need a single ended ADC but didn't knew the 2450 existed... small problem: only available in DFN apparently, so yeah... I'll stay with the 2452 and the half Vref bias to make it single ended ?

The unit gets power from the cell under test (voltage >2.5).

That's not a good idea, see below.

Use a

ADUM1201 for serial clock and MISO isolation. Will use a simple opto isolator for chip select. The two SPI signals will be daisy chained 4x. Not sure that's a problem. Chip select gets a direct (isolated) signal from the controller.

Not a problem if 6 isolated signals for 4 cells isn't a problem for you

Does LTC2452 Vcc require a regulated voltage? Or is a direct cell connection adequate?

Well,

the datasheet shows Vcc range is 2.7 to 5.5 V and that Vref min is 2.5 V. Also the PSRR is 80 dB which doesn't sound a lot for a PS which will change wildly (didn't made the maths tho). So it's not gonna work. If you want to stay with this ADC the simplest thing to do would be an isolated DC/DC converter fed from the 3.3 or 5 V of the ESP.

Reference voltage should be around 2V. Or use higher voltage with resistor divider. I don't think that should be an issue. Initial accuracy shouldn't be a problem as calibration will take care of that. Tempco? as good as it gets.

Edit: Ref voltage can't be greater than LVD. 2.5V is max.

Well, given what I said just above you might want to change your ADC model so I'll wait before recommending a Vref because it depends on the ADC specs.

When I selected this ADC I was looking for some specific things, like for example a 5 V Vcc, but you have significant different requirements: single ended would be better (because currently you'll have a 15 bits ADC really), I²C, wide Vcc going lower than 2.7 V, ... so I highly suggest you use a better suited ADC.

Thing is, direct powering isn't a good idea as there's

very few ADCs going lower than 2.7 V (and they's only available in very small packages), plus you would still have the PSRR problem, etc...

Here's

a parametric search for 14 to 16 bits ADCs, single ended, I²C, in nice packages (DIP, SOIC, SOT), sorted by price. As you can see the 2451 is your best bet, but in any case you'll require some stable power supply around 3 to 5 V.

Also I would highly recommend a MUX instead of 4 ADCs as it'll be less expensive, lower power, needs only 4 isolated lines instead of 6 for 4 cells and would require only one isolated DC/DC converter instead of 4 (and those are very expensive...)

You can also

widen your choice a bit by selecting other type of interfaces (basically I took all excepted parallel) but the 2451 is still the best bang for your buck.